Announcement

Collapse

No announcement yet.

101 Scout... going to take a while

Collapse

X

-

Could it be that your front guard is off 29-30 indian 4? Same style but i think they had a longer fork like a chief hence why your braces are more suited to a longer fork?

-

The front fender for my 1929 Four (same as 101) is a little rough but also measures 31 inches.

Tom

Leave a comment:

-

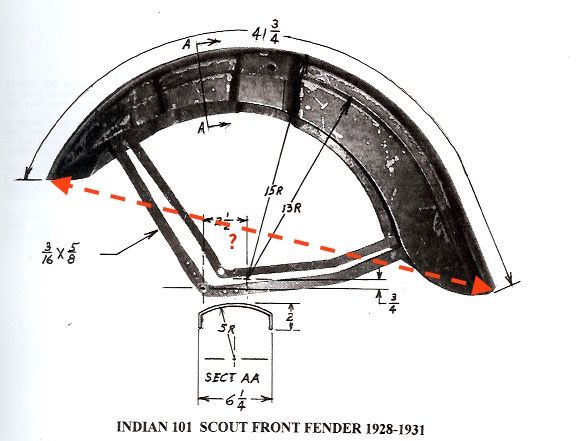

I'm hoping someone can give me a measurement next time they remove their front wheel? I'm still having difficulty fitting the front fender and I suspect the arc of the fender is either too flat or too tight, and I'd like to use the original braces and holes. Thanks in advance!

Leave a comment:

-

It’s good to see someone else working on a 101. I had to make the brackets for my fenders and it took forever to get everything lined up correctly. Good luck and keep posting.

Leave a comment:

-

For some strange reason the pictures don’t show on my I-pad. They do show on my desktop machine.

Now they don't even show on my desktop...so I reloaded them. Strange!Last edited by pisten-bully; 06-26-2019, 05:57 PM.

Leave a comment:

-

And I've got the spokes and nipples all painted so that I can lace the hubs to the rims.... realizing of course that checking sheet metal fit without wheels is not the best thing to do!

Last edited by pisten-bully; 06-26-2019, 05:54 PM.

Last edited by pisten-bully; 06-26-2019, 05:54 PM.

Leave a comment:

-

Haven't posted in nine months, sorry 'bout that!

I've been chipping away at small stuff and just recently started to try and hang some sheet metal. The fenders have been "roughed in" with the cracks welded, extra holes welded up, and the larger dents rolled out, but nothing approaching a finished appearance until I can get them fitting correctly.

The rear fender went on fairly smoothly, but I've got a large gap between the generator/seat spring plate and the fender:

The front fender fit nicely in the forks, but I'm looking at some fit problems where the fender stays are bolted to the fork down low.

The lower brackets between the stays that fit onto the fork and rocker bolt are nowhere near where they belong....

Last edited by pisten-bully; 06-26-2019, 05:56 PM.

Last edited by pisten-bully; 06-26-2019, 05:56 PM.

Leave a comment:

-

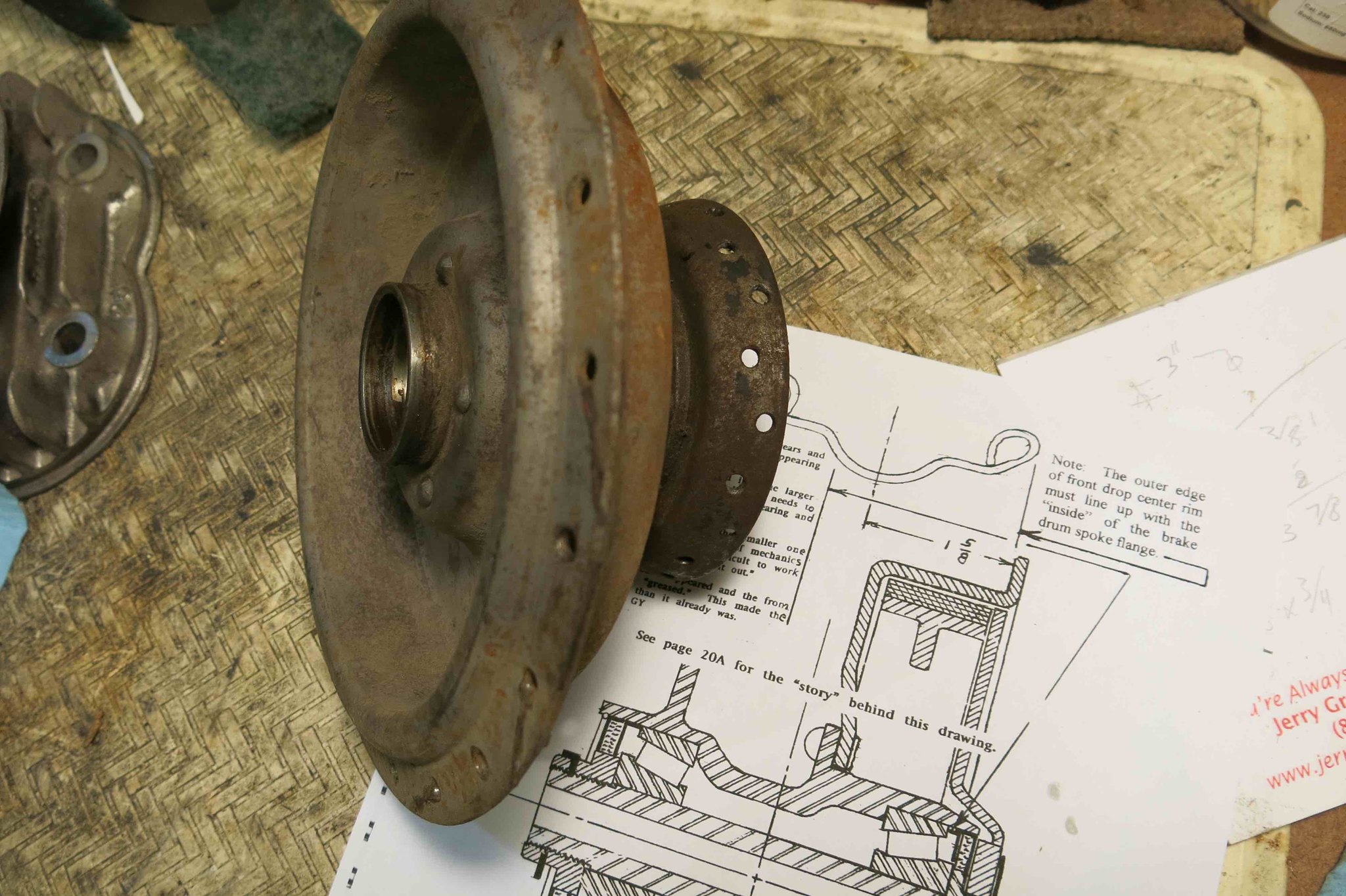

Thanks Jerry, this one is 3 1/8" wide. I put a listing up as I'd love to see it go where it's needed (and to recoup some of the cost to acquire the correct one from Kent Thompson!)Originally posted by Jerry Wieland View PostThe hub looks like JD Harley or early WL - they are similar except for the width. Jerry

http://www.antiquemotorcycle.org/bbo...737#post174737

Leave a comment:

-

The hub looks like JD Harley or early WL - they are similar except for the width. Jerry

Originally posted by pisten-bully View PostI got a bit of interesting information on my front wheel hub this morning (thanks to the sharp eyes of Dave on the Caimag site), until he mentioned the dished flange away from the brake side, I had never paid attention. Brake drum, spoke count, and rim size all looked good.... but this is not the correct hub! I measured it up and it's way wrong.... sheesh. So now I need to figure out what it is and where to get the correct hub. Makes sense that it's not the right one, the rear wheel that came with it turned out to be Henderson. One step forward and two steps back....at least I hadn't painted it and laced it up to the new rim!

Leave a comment:

-

I don't, but I think it's visible on the table in one of those pictures?Originally posted by rustynutz View PostVery interesting work, do you have any pictures of the die they made to crush the tubing?

Leave a comment:

-

Very interesting work, do you have any pictures of the die they made to crush the tubing?

Leave a comment:

-

time to deal with the fork, the front stays were dented in multiple spots on both sides and I investigated straightening the existing tubes, but when it all was said and done I wanted a set of forks that were properly braced. The fellas at Race Metalsmiths took a look at the fork and came up with a plan, a few of the many dents in the stays:

Brothers Scott and Mitch convinced me that replacing the tubes was the best way to go. The old tubes were cut off and solid slugs were brazed into the casting for the new tubes to slide over and be brazed in place;

Mitch made a die so that the crushed tubing on the lower end, where it's brazed to the main fork, matched up perfectly with the original crush:

New tubes were made that matched up exactly with the old ones that were cut off, they used 4031 chromoly tubing... should be safe forks!

One of the things I struggle with is the decision to do it myself or let someone else do it. The guys at Race Metalsmiths know their stuff and are sensitive to matching new fabrications up to original. Lots of things are beyond my pay grade so I let the pros do it!Last edited by pisten-bully; 09-26-2018, 11:53 AM.

Leave a comment:

Leave a comment: