Announcement

Collapse

No announcement yet.

101 Scout... going to take a while

Collapse

X

-

I am so envious of your project, and what you are doing, Harry. I wish there were more 101's out there. I guess we just have to enjoy the motorcycles we do have, and the time we spend with them.

Leave a comment:

-

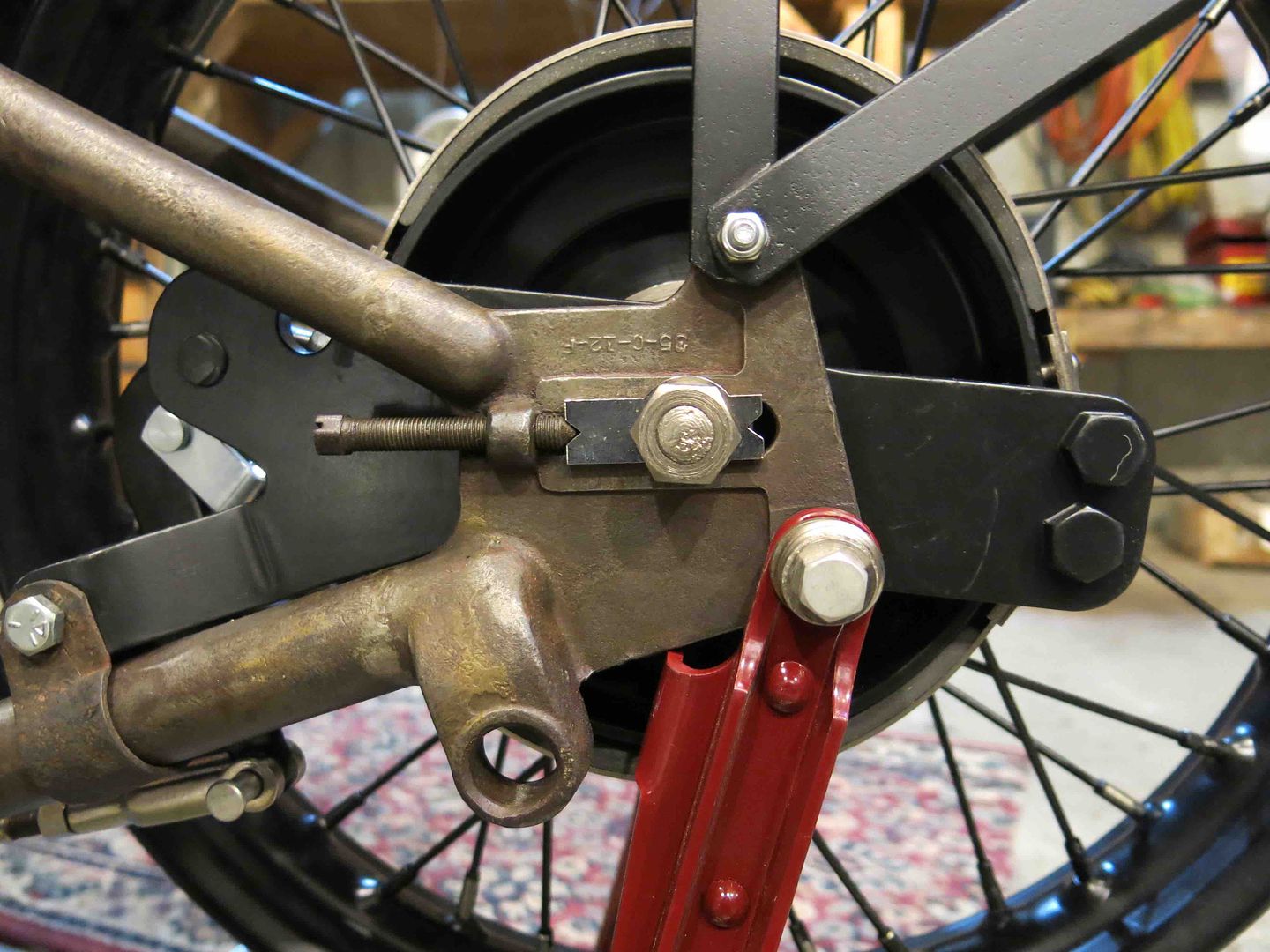

The brake cross shaft has another bell crank on the LH side and another rod connects that to the brake actuating arm

The re-pop rod had a 90 degree bend on the bell crank end, but Indian changed that rod in 1929 to threaded with a clevis on the bell crank end. I couldn't get the 90 degree rod end to fit between the frame and the bell crank so I cut it off, threaded it, and installed a clevis to make it fit.

So now everything is all connected and I'm just wondering how the brake bands will conform to the drum! I'm supposing that on my first ride I'll have a rear brake for a few yards then not much after that until I re-adjust?

Again, I've found that everything needs some sort of an adjustment to make it fit. Re-pop parts mixed with original!Last edited by pisten-bully; 01-13-2020, 05:05 PM.

Leave a comment:

-

I've been fitting some of the little things, like the rear brake. The brake pedal on the right connects with a rod to a bell crank which is on the end of a cross over shaft:

I have the original cross shaft but the key way on the RH side was wallowed out a bit

I went ahead and had it re-plated and then I tried to solder my way out of trouble by repairing the key way with solder (this may not be the best solution!)

Last edited by pisten-bully; 01-13-2020, 05:04 PM.

Last edited by pisten-bully; 01-13-2020, 05:04 PM.

Leave a comment:

-

That is looking so good, Harry. Thanks for keeping your project updated. The 101 had such good lines.

Leave a comment:

-

I needed to spread the forks to 5 3/4" before they would settle in at the needed 5" width, and I wound up restraining the forks higher up so that I was only spreading the lower part, but it all came together.

The exhaust fit with lots of fiddling around (I have a used European re-pop exhaust that a friend gave me which came off of a 45" 101....lots of fiddlin'!). Headed back to set up the kicker next and I'm expecting more fiddling... so far nothing on this project has been "bolt on"

Leave a comment:

-

Mikeís thoughts are good, thanks ...and Kevinís got another angle Iíve got to pay attention to...so thanks...I donít want the fork to look like Cottenís one picture that seems to be making room for a hay wagon tire (love that picture!)

Havenít been back to the 101 since I posted that, instead concentrating my motorcycle time on taking one last ride and on putting the Chief to bed....got cold fast and now thereís snow on the ground!

Leave a comment:

-

That works on girders, Harry!Originally posted by pisten-bully View Postdo I continue to spread farther and farther and release, going in 1/2" steps until I get the desired 5" to stay in place, or should I be thinking about some other method?

....Cotten

PS: I always wanted a 'portapower';

Fortunately, this Hen owner brought his own.Last edited by T. Cotten; 11-10-2019, 11:49 AM.

Leave a comment:

-

When you spread the forks out, were the rockers still aligned enough that the axle would pass through them?

Kevin

.

Leave a comment:

-

I am far from being anything but a metal bending hack. Wonder if you need some slight reversed pressure/restraint up further on the forks to delicately allow ever so slight bending and counter act the memory as you expand out from the bottom. Possible another all thread with plates on each end tightened instead of expanded. I wouldn't know where to restrain it in the upper area for the fork - maybe at the point where the rim is? It probably would not take much to change the memory of the steel.Originally posted by pisten-bully View PostI am wondering about the following: when I made a first attempt to fit the front wheel with the rockers installed I found the spread of the forks is too narrow. The hollow axle requires about 5" of width between the mounting holes and I only have about 4 1/2". So I rigged up a simple way to spread the forks, or actually the axle holes in the rockers, to 5". It didn't really take much force to get there, but when I release I lose almost all that I gained. So my question is, do I continue to spread farther and farther and release, going in 1/2" steps until I get the desired 5" to stay in place, or should I be thinking about some other method? Thanks!

Leave a comment:

-

I am wondering about the following: when I made a first attempt to fit the front wheel with the rockers installed I found the spread of the forks is too narrow. The hollow axle requires about 5" of width between the mounting holes and I only have about 4 1/2". So I rigged up a simple way to spread the forks, or actually the axle holes in the rockers, to 5". It didn't really take much force to get there, but when I release I lose almost all that I gained. So my question is, do I continue to spread farther and farther and release, going in 1/2" steps until I get the desired 5" to stay in place, or should I be thinking about some other method? Thanks!

Leave a comment:

-

Ah, well then! Thank him for his service!Originally posted by pisten-bully View PostWe all dodged the bullet, he switched from flying people on SW to motorcycle parts on UPS...whew!

Kevin

.

Leave a comment:

-

We all dodged the bullet, he switched from flying people on SW to motorcycle parts on UPS...whew!Originally posted by Shaky Jake View PostWhich airline? Just wondering... ;-)

Leave a comment:

-

I was thinking the same thing!Originally posted by Shaky Jake View PostWhich airline? Just wondering... ;-)

Kevin

.

Nice work Harry!

Dale

Leave a comment:

-

Which airline? Just wondering... ;-)Originally posted by pisten-bully View PostAhhh... the Porta-Power! Funny thing, I purchased that when my now 40 year old son was 18 and bent the cross member in a 4-wheel drive we had when he hung it up on a stump...he also rolled three different cars! Now he's an airline pilot.... I told him I hope your rolling days are over!

Kevin

.

Leave a comment:

Leave a comment: