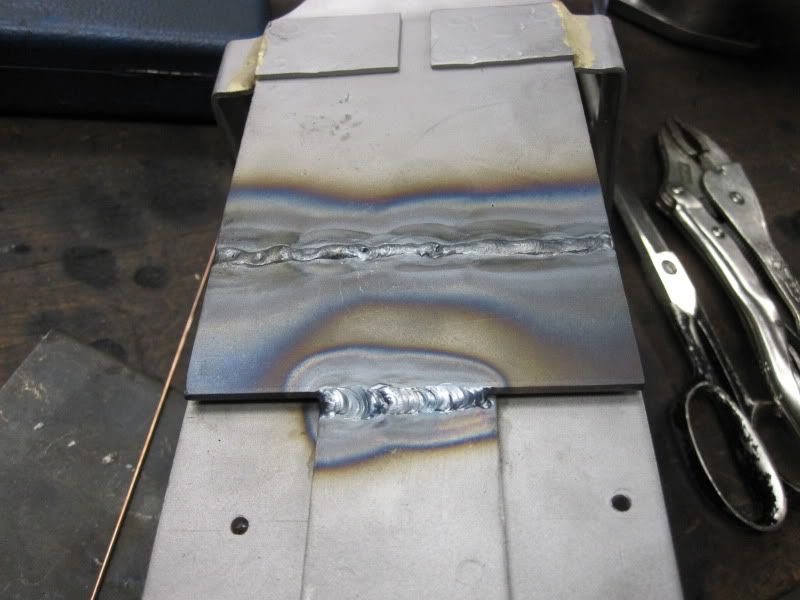

Great work guys especially Ryan. We are all impressed and envious. I like the paint layout on the tank and think that the silver a black sheet metal will really compliment the overall bike. You could also incorporate it into the fender skirts and rib. Very enjoyable reading your progress.

Paul

Paul

Comment