What about me? I'm not gonna have anything to read for months! C'mon summer!

Announcement

Collapse

No announcement yet.

Ryan's A.M.C.A. Giveaway bike build!

Collapse

X

-

Ryan, I have enjoyed following along with your Bike Build. I have recent finished a 1950 WL done as a '50's era Bobber. My wife & daughters wanted a bike they could learn to ride. They think my big-twins are too heavy. I like your paint idea to include scallops on the tank. Mine are Azure Blue (1950 color) and the rest is Daytona Ivory (1954 color) Here are some othe bikes with scallop paint. Joe Weatherly

Booze Fighter's

and the '50 Bobber

Keep up the good work. Soak up all the knowledge you can. Tim

Comment

-

Good job guys!! In one of your previous posts you are shown torqueing the cylinders. You are using an extention of some sort from the wrench to the nut, for clearance reasons I assume. I have often wondered how such a setup will affect the torque being applied. Is there some sort of formula you use depending on the length of the extention or doesn't it matter?

Comment

-

Tim,

Your 50 looks amazing! Give me a call next week, I need your address so I can send you out a long over due care package.

John,

The torque wrench has the same reading when the amplifier is straight, but when you have the amplifier installed 90 degrees to the torque wrench, you have to plug the numbers into a formula. I think it is 70 to 80 percent of the actual reading, I will check and get back with you.

Everybody else,

The updates will not come to a screeching hault next week, they will just slow down a little bit. Ryan will start on his body work and paint job with Larry Medwig when he gets home, and I have to send a lot of his stuff off for plating.

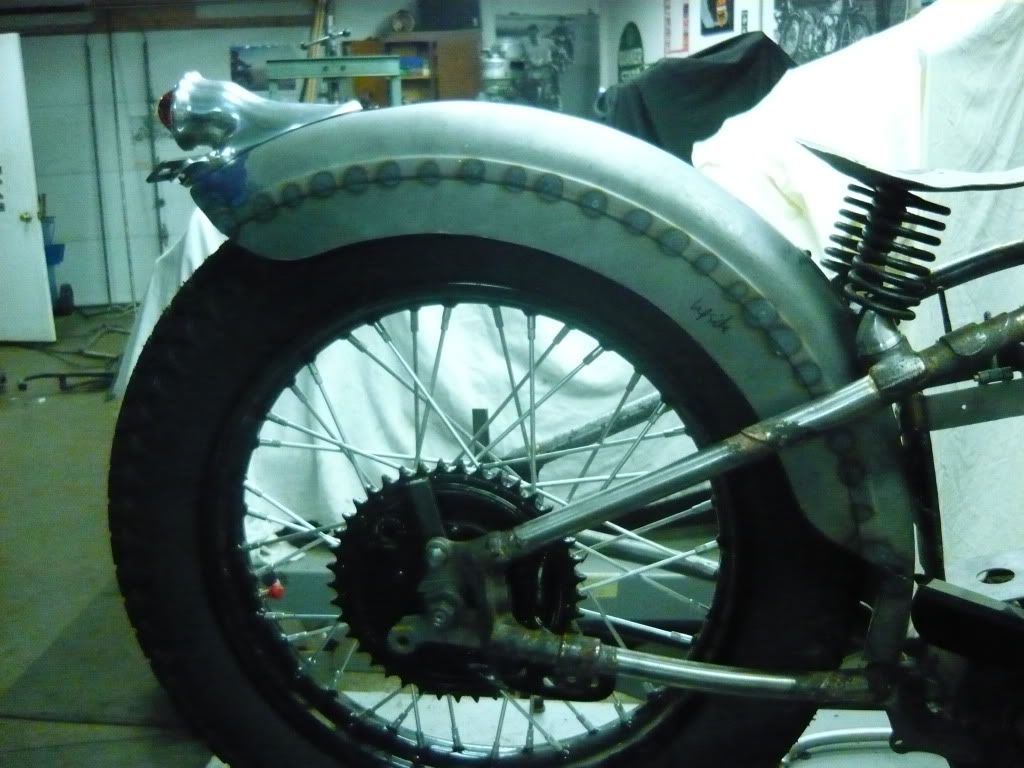

This morning I spot welded Ryan's skirts in place. Ryan made the skirts out of .060 thick metal, which is pretty heavy. The reason that we did this is because our shop doesn't have the capabilities to fold over a lip on the edge like stock fenders. The plus side of using a heavy guage metal is that it makes the fender really rigid.

Here is a pic of the other side! There were a couple spots where we burned through the metal, so it needs a little bit of finish work. Ryan and my dad are knocking out the braces right now.

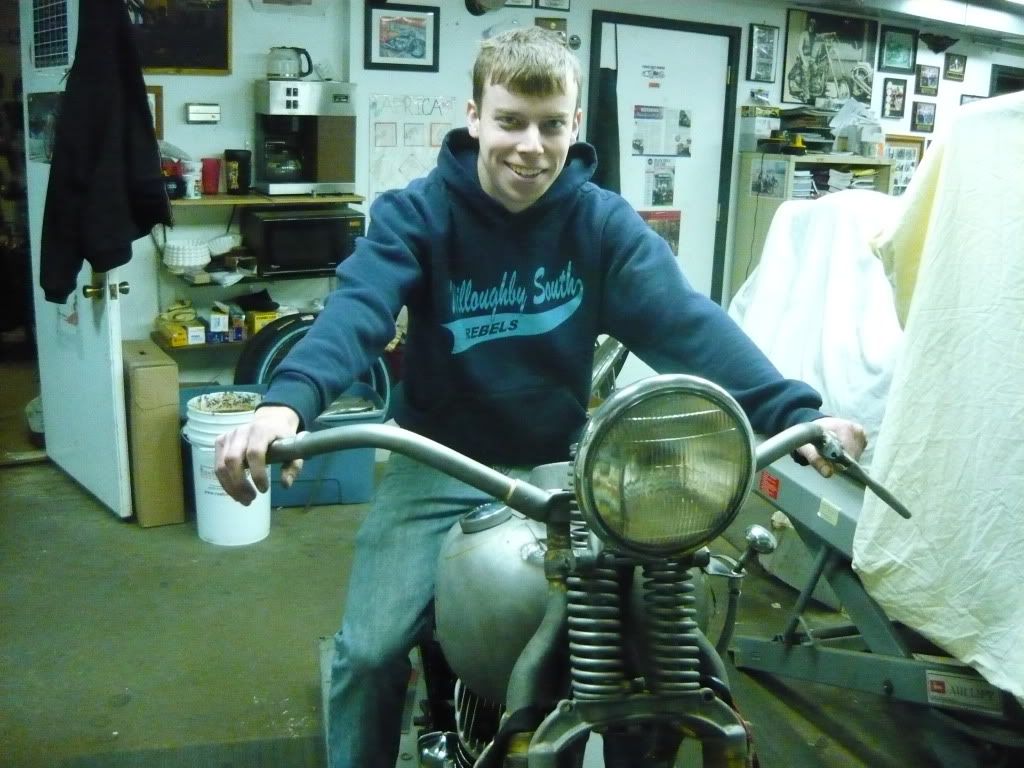

Ryan on his bike! My dad and I tried to talk him into making motor noises, but he wouldn't do it. Ryan and I are getting interviewed by Tom Lowdermilk tonight on www.sidestandup.com. Check it out and have a good day!

Comment

-

I made a mistake in regards to the little torque amplifier in my previous post, and the edit feature did not seem to want to work. It should read the torque amplifier reads the same at a 90 degree angle, when the amplifier is in line with the wrench you have to plug the numbers into a formula which makes the final reading 70 or so percent of the actual reading because of the increased leverage! If you don't have a torque wrench, you can just tighten them up as tight as possible, that is what I do when I am out on the road, and it works just fine.

Comment

-

We basically finished up the fender today! I made some brackets to mount the back brace on this morning. Here they are after I drilled and tapped the holes and layed out how I wanted them.

And here they are after some cutting and shaping. They are going to be mounted on the inside of the frame instead of the outside like stock so that the brace does not have to bend out as far. I also decided to get them nickel plated before we rivet them on.

Here is the fender with the brace and the tail light mounted!

The only thing left to do is weld in some clips that I made to hold the wiring under the fender. Matt had a sample for me to copy.

Here they are after I bent them up.

It was really nice outside here for a change so we decided to take the bike out and take her for a test ride.....well ok not so much a test ride but I can dream can't I?

Here I am with my new baby and the guys that I owe all this too!

The plan tomorrow is to finish up the fender and then start fitting the dash. I only have 4 more days to work before I have to fly home!

Comment

-

Ryan, good job on the build, it must be killing you not to finish it up! If you decide you can't stand it and decide to finish it earlier we would love to have it at our Southern Meet in Denton, NC in May. We are planning a youth rider/builder award to support the youth program, just display your bike on Sunday to be eligible.Louie

FaceBook >>>Modern Antique Cycle

Blog Site >>> http://louiemcman.blogspot.com/

YouTube >>> LouieMCman

Comment

-

Yeah I'm still not quite sure how I am going to manage being away from it for so long. I guess its better though than having to try and study for school with it in the garage begging to get ridden. We all know how that would end...

Unfortunately I don't see that happening but if it is a yearly thing, I'll be sure to mark it on the calender for next year!Originally posted by LouieMCman View PostRyan, good job on the build, it must be killing you not to finish it up! If you decide you can't stand it and decide to finish it earlier we would love to have it at our Southern Meet in Denton, NC in May. We are planning a youth rider/builder award to support the youth program, just display your bike on Sunday to be eligible.

We got the tin for the battery box in the mail today. All it needs are some spot welds and it will be done!

I started working on the dash strip that covers the gap between the 2 tanks this afternoon. It has a relief shaped into it where the seat pan would normally mount to the frame but since I am not running a stock seat pan, it needs to get reshaped.

And here it is after I did some hammer and dolly work.

It still needs some more work but here it is on the bike. I will also need to make a couple filler strips to fill in the slots.

Comment

-

Ryan

Leave the slots in the trim, you may find that down the road a proper seat mount will give a better ride than the short pivot arraignment you are currently setting up. Beside on a proper bobber these things are acceptable and wonít affect the style one ounce. The battery box looks like new good job fabricating.

Joe

Comment

-

Ryan,

Your bike is looking fantastic. Maybe I'll get to meet you someday in Chagrin Falls, close to home for you. I work there now. I think the entire club owes a great "thanks" to Carl & Matt for this effort. It shows what this club is made of. Also, thanks for the daily update, it sure is entertaining. This winter is already too long. -BobBob

Comment

-

I have thought about your idea but since we had to cut the bracket on the frame because it normally would stick through the slots, it would just seem more finished to me with the slots filled. If I ever decide to switch back, I can just either cut the slots in or find another one to switch out.Originally posted by Slojo View PostRyan

Leave the slots in the trim, you may find that down the road a proper seat mount will give a better ride than the short pivot arraignment you are currently setting up. Beside on a proper bobber these things are acceptable and wonít affect the style one ounce. The battery box looks like new good job fabricating.

Joe

Thanks man, we will definately have to meet up sometime and go for a ride.Originally posted by bobdo View PostRyan,

Your bike is looking fantastic. Maybe I'll get to meet you someday in Chagrin Falls, close to home for you. I work there now. I think the entire club owes a great "thanks" to Carl & Matt for this effort. It shows what this club is made of. Also, thanks for the daily update, it sure is entertaining. This winter is already too long. -Bob

Yesterday Matt and I took a little break from the bike and went to his friend Ben Victor's place. Ben is a sculpture and the guy that does his wax molding, Dan Ochs, was in town doing some work for him. Since Matt needed some molds made for his Sears, it was the perfect time for him to take me to check some of this stuff out. It was really cool to see the process of how the molds are made before they are sent to the foundry. Here are Matt, Dan, and I next to one of Ben's sculptures that he is working on.

After we got back Carl and I got to work on the dash. The right side was way off when we first put it on. The first thing I did was egg shape the mounting holes on the oil tank to help move it up some. That helped a lot to take up some of the gap. The rest was taken care of by bending the dash around a little bit. It turned out really good.

The switch still needs a little bit of work so that it mounts flush but it shouldn't be too difficult.

We also got the fender all done! Matt and I welded in the clips to hold the wiring to the tail light in on the underside.

Last night I made up some mounts to mount the spring to the seat. I started with some 1" round stock.

And with a little bit of time on the lathe, here is what I came up with. It will get welded on the bottom of the seat pan and is a snug fit into the top of the springs.

This morning I got the front brake parts in the mail. We are supposed to get the rims and hubs back from powdercoating today as well so hopefully I will be able to lace up the wheels and put everything together.

Comment

Comment