that wire loom weaver is awesome. what an awesome experience.

Announcement

Collapse

No announcement yet.

Ryan's A.M.C.A. Giveaway bike build!

Collapse

X

-

Yup I was there all day friday and most of saturday. It was really nice seeing everyone again that I had met at Denton and meeting a ton of new people. The races were awesome. Those guys are crazy!!

I didn't get too many parts but I did get some grips for my bike thanks to Maiden America!

I have to say by far the coolest bike that was there was the '36 that Matt and Carl just finished. It is number 1005!

I fly back to South Dakota Thursday so stay tuned...this bike should be cruising down the road in no time!

Comment

-

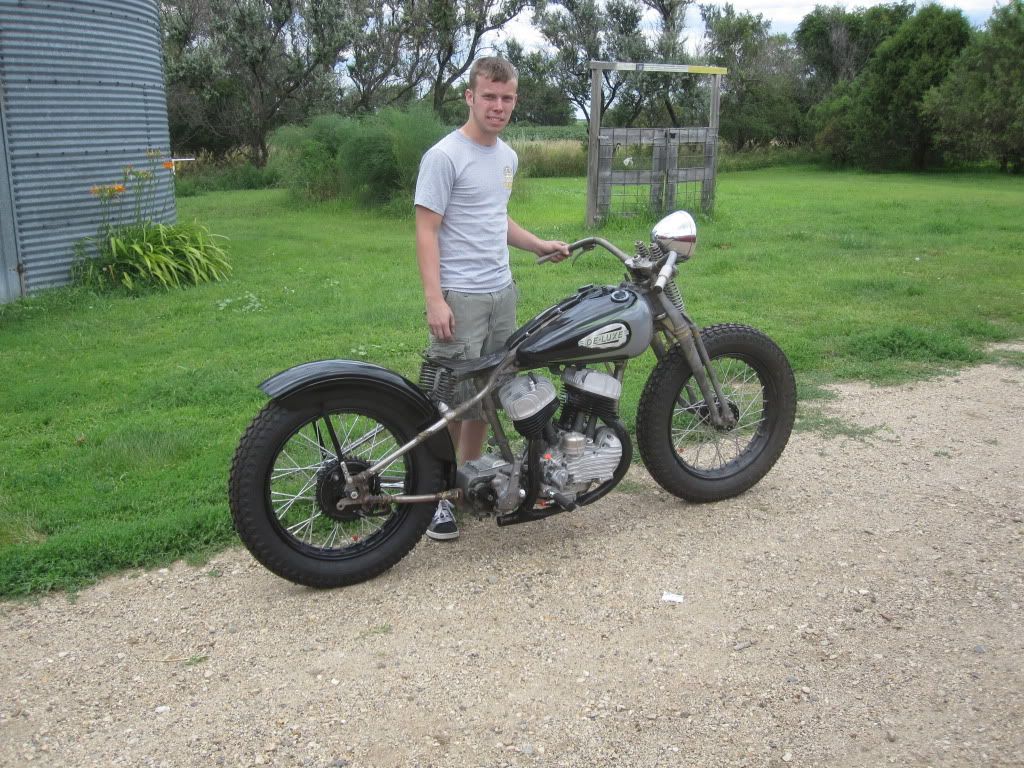

I arrived in Aberdeen around 1 this afternoon and didn't waste any time getting to work. First things first though we had to see if I had grown at all while I was gone or if Duke the shop dog was still taller than me...you can be the judge

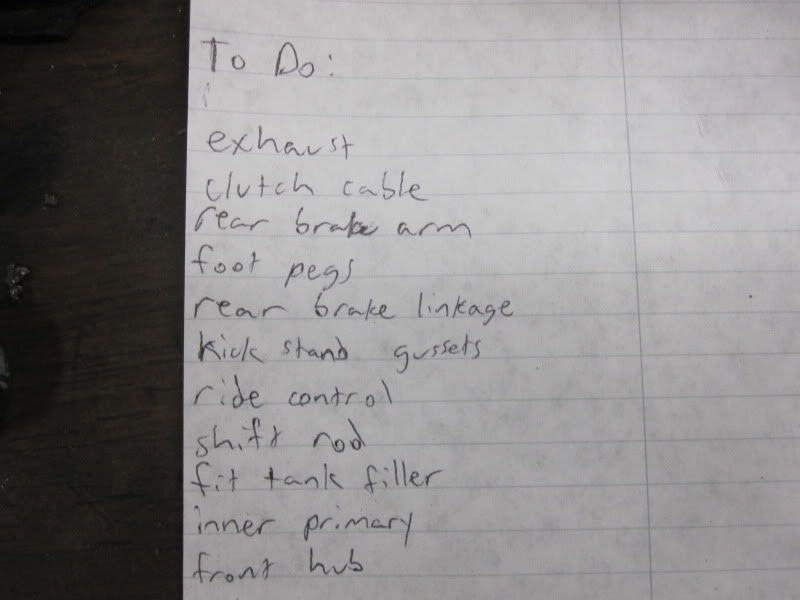

After that was settled I made a list of all the things that still need done...a lot to do in 2 weeks!

First I got started on the foot pegs. I got them at Denton but the threads were the wrong size for the shaft that we made so I put bolts in, cut them flush to the mount and then welded them in. Then I used the lathe to face the welds and then drill and tap the new threads.

The pegs do sit out a little farther than I would like so we are contemplating cutting them a little shorter.

After that it was dinner time and since this will probably be the last chance that we have any time to leave the shop to eat, Matt and I decided to go ride and grab some food. Here I am on their '47 knuck

When we got back, I started working on the brake lever. When Matt welded it up for me, it melted the brass bushing so I filed it down as much as I could and then Matt showed me how to hone it out to get it nice and smooth.

Luckily I got a good nights rest last night because we only have 2 weeks to get my bike done for Sturgis...there isn't going to be much time for sleep.

Comment

-

You can sleep when you get old, for now, git 'er done!Lonnie Campbell #9908

South Cackalackey, U.S. of A.

Come see us at the Tenth Annual AMCA Southern National Meet - May 17-19, 2019 at Denton FarmPark, Denton, N.C.

Visit the website for vendor and visitor information at www.amcasouthernnationalmeet.com

Comment

-

It was nice meeting you too.Originally posted by Slojo View PostRyan

It was my pleasure meeting you at Wauseon Ohio this past weekend. Happy to see you back in the saddle. Now get back to work.

Joe

Yesterday I worked most of the day on the ride control. Its going to be so cool when it is done. I did get to shorten the foot pegs though last night. I had to section a piece out of the middle since the ball on the end helps keep the rubber on the peg.

Here is the difference, I shortened them by 3/4".

I already got some spacers for the ride control machined up this morning. Hopefully we will be finishing it up today.

Here is how the bike looks right now. We had to take some pictures for the magazine.

Comment

-

Thanks! Sorry I missed you, I will be at Davenport so if you are there be sure to chase me down.Looking really good Ryan ! I thought I saw you scrolling around at Wauseon. I was unable to catch up with your quick legs though.

I got a few things checked off the list today. The ride control is finally all welded up, it still needs a little work but it is basically done. It took a lot of machining and trial and error but I think it looks awesome!

I got the front hub all put together then decided to throw the wheel rings on the rear wheel. Check that out!

There was no time for having a nice candle lit dinner so I had to make do and eat standing up in the shop.

I also made up the ends for the clutch cable. I used an original wr cable to copy.

Comment

-

More and more is getting marked off the list everyday. Today I worked almost the whole day on making blocks for the cables and wires to run through. Nobody donated any so I made some similar to the one's that are on Matt's Sears. I started with 3/4" square stock and milled it down on 2 sides to get it to the right dimensions I needed.

Once it was the right size, I cut them to the right length and then drilled the holes. After the holes were drilled, I took them to the belt sander and shaped each one individually. 3 of the blocks had to also have a set screw in them to tighten the cables down.

It was extremely time consuming but in the end it was totally worth it.

I also fit the inner primary tonight.

You can see that it was touching on the transmission which is not good.

But its nothing that a little sanding won't take care of.

Comment

-

Today a master fabricator and industry giant came up from Minnesota to help Matt move along on his Sears. Kevin Baas is a high school teacher that started a class that teaches kids how to build motorcycles. How cool is that! He is going to spend a couple days here working with us.

While Kevin and Matt worked on Matt's Sears I got my primary all set up and then mounted my outer primary cover. I ended up having to shave about 1/4" out of the bottom of the inner primary to get the outer primary to fit nice. Once that was done, I started messing with the clutch cable when I realized I had a problem. When I would push the clutch pedal down, the cable hits the primary cover. After thinking about, talking it over with Carl, and digging through some old parts we came up with a solution. I decided to make a roller for the cable to sit on the would keep it off the primary.

First I drew a picture and started taking measurements trying to figure out exactly how I was going to make it. I started with a piece of 3/4" hex stock and machined it in the lathe.

Here I am cutting some threads!

The final product...

And here it is all mounted up

After that was done I worked on the kickstand mount.

The shop was full of people working...even Matt's mom came out and got her hands dirty!!

Comment

-

That is a very cool idea Ryan ! May I suggest you drill a small grease fitting hole into the roller shaft and intersect that hole horizonally under the roller ? Also....may I also suggest you add an L shaped brace over the roller to prevent the cable from jumping off of the roller ? Paps

Comment

-

Thanks for the ideas, I am definitely considering them but will work on it more probably in a few days. I did end of having to make another piece with a bigger back spacing because the cable ended up sitting out a little farther than I had first thought. It works good now though!Originally posted by Paps View PostThat is a very cool idea Ryan ! May I suggest you drill a small grease fitting hole into the roller shaft and intersect that hole horizonally under the roller ? Also....may I also suggest you add an L shaped brace over the roller to prevent the cable from jumping off of the roller ? Paps

Kevin and I worked on the exhaust yesterday and got most of it done. I decided to make a wr style tip on the end. To do this I cut down the middle of the tube on either side as parallel as possible with each other.

Then heated the tube up at the end of the cuts and bent it up.

After that cooled I cut out 2 triangle pieces to fit in the gap and Kevin welded it up for me. It still needs mounted but we will do that later.

Kevin brought his knucklehead up to put on a side car that he bought for his kids. Before we started working on it, he let me take it for a spin.

I saw it in a magazine a while ago before I won this bike and always thought it was the coolest bike...who would of thought a year later I would get to ride it!

Here is Matt and Kevin getting ready to go test the side car.

And here is Carl and I testing it...

Once we were done having fun we got back to work on my bike. When I rolled it off the lift I realized that the kick stand let the bike lean over way too far. After a lot of brain storming we decided it was best to move it under the primary so I was up til about 3 this morning grinding it off and then had to get up early to weld it back on in a better spot so that we could send the frame off to get powder coated by noon. It should be done by tomorrow afternoon so we can start putting everything together for good!

Comment

Comment