Thanks everyone. When your little most kids ask for pony's or trucks and stuff...well I always asked for a motorcycle and whatda ya know it came true!

It definately has been a white Christmas here in South Dakota...

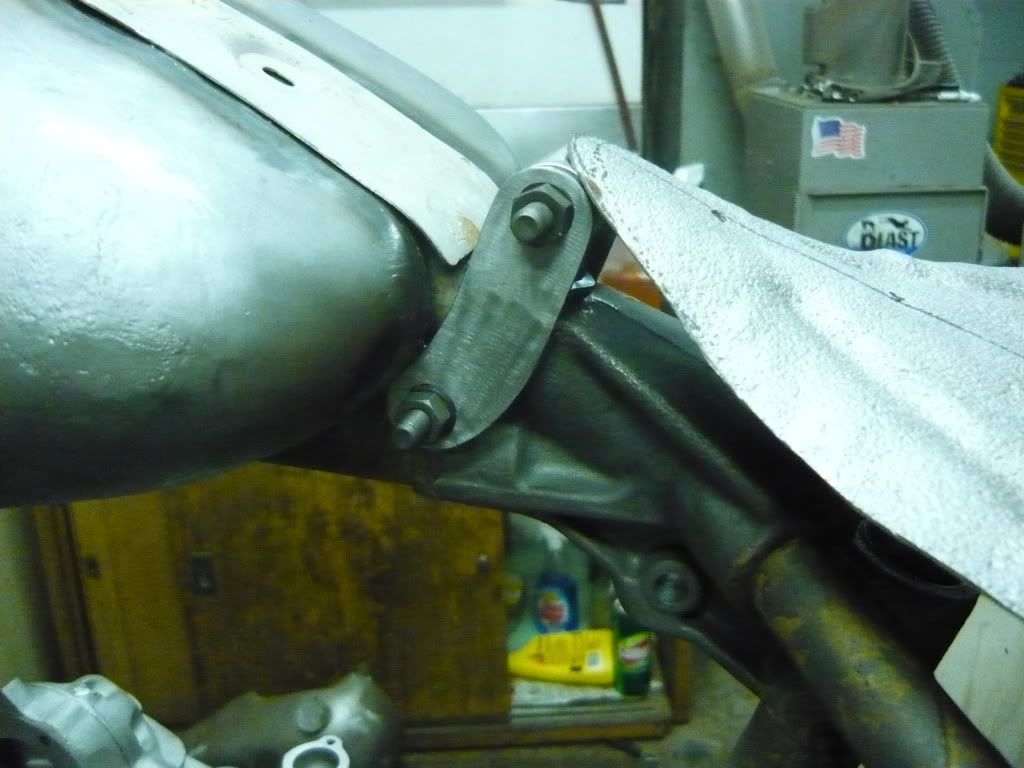

Matt and I were at it again early this morning. We lowered the headlight to flow a lot better with the rest of the bike. Here it is stock before I cut it.

It would have looked weird stock. I enlarged the second hole on the lower mounting tabs and then cut off the first one that would normally be used to mount it. I also had to bend the top mount down and cut it shorter to fit right.

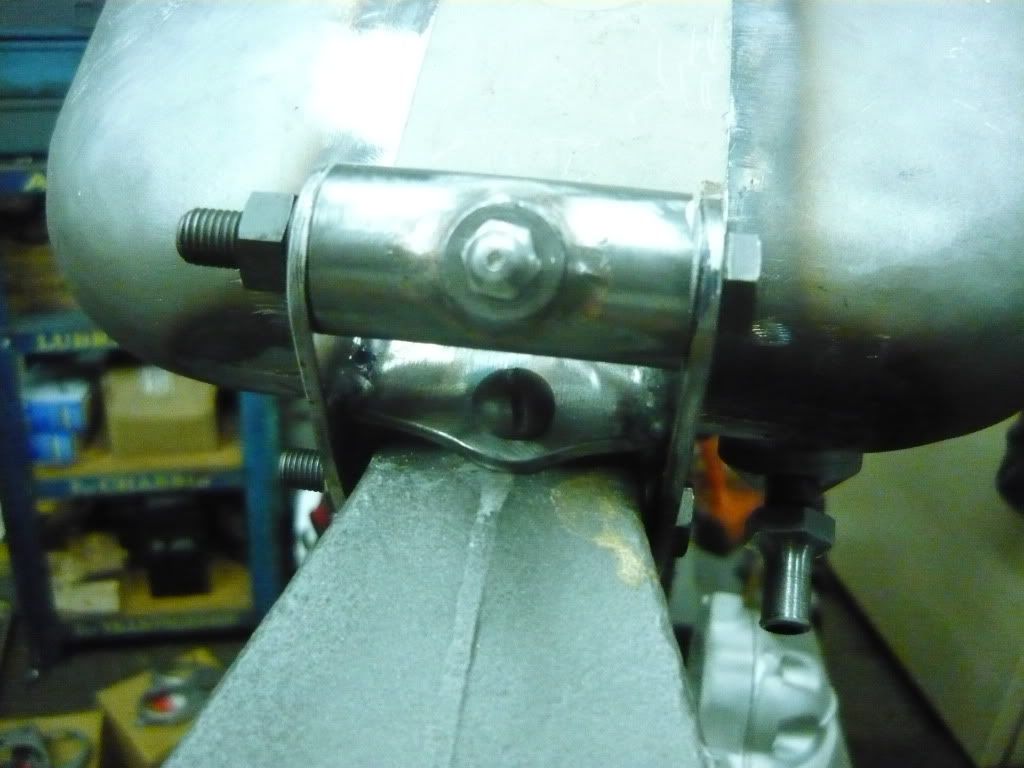

Here it is all mounted.

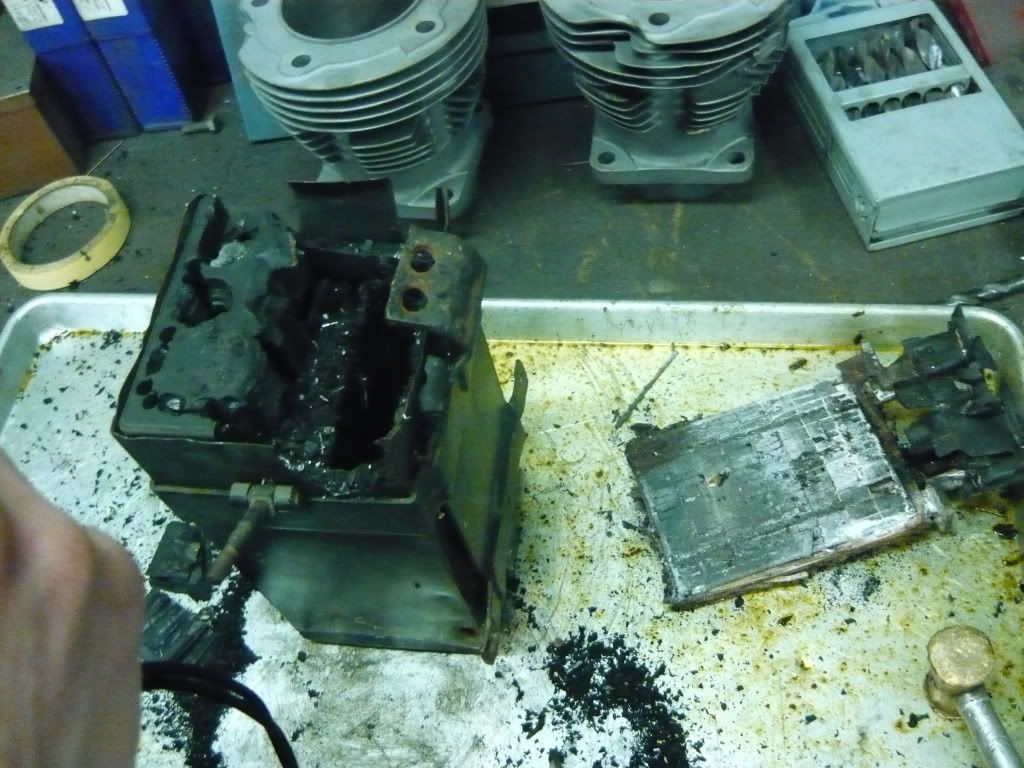

After we have our Christmas dinner we are going to continue working on the seat. I am cutting a stock seat pan down similar to a wr seat

It definately has been a white Christmas here in South Dakota...

Matt and I were at it again early this morning. We lowered the headlight to flow a lot better with the rest of the bike. Here it is stock before I cut it.

It would have looked weird stock. I enlarged the second hole on the lower mounting tabs and then cut off the first one that would normally be used to mount it. I also had to bend the top mount down and cut it shorter to fit right.

Here it is all mounted.

After we have our Christmas dinner we are going to continue working on the seat. I am cutting a stock seat pan down similar to a wr seat

Comment