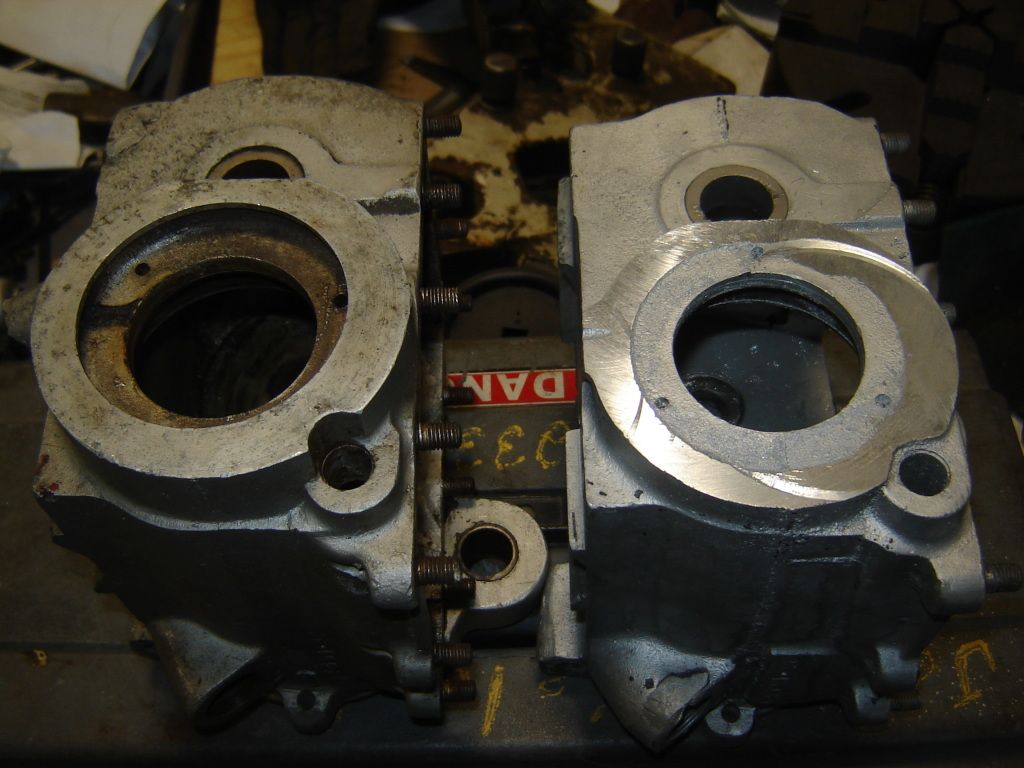

Today my special tap (5/8" x 14tpi) arrived so I was able to make the rest of my steering dampner conversion. Here is the stock stem.

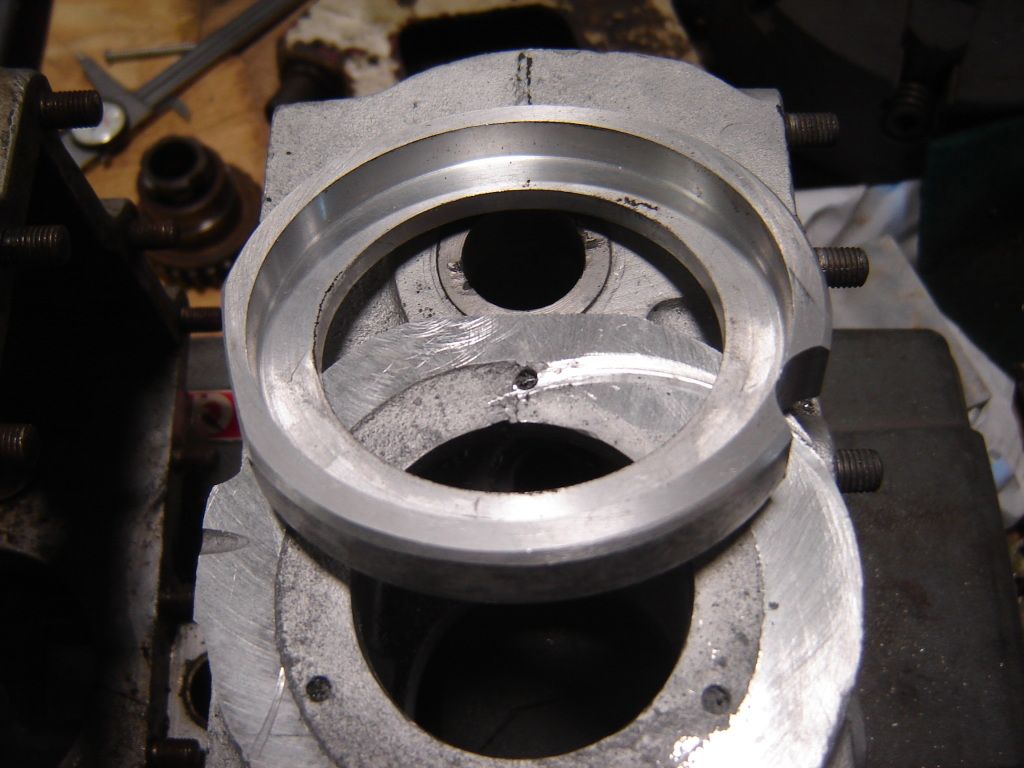

I made a threaded insert that accepts a WL type thread. and pressed it in to the stem. I then proceeded to tig weld it in to the top of the neck.

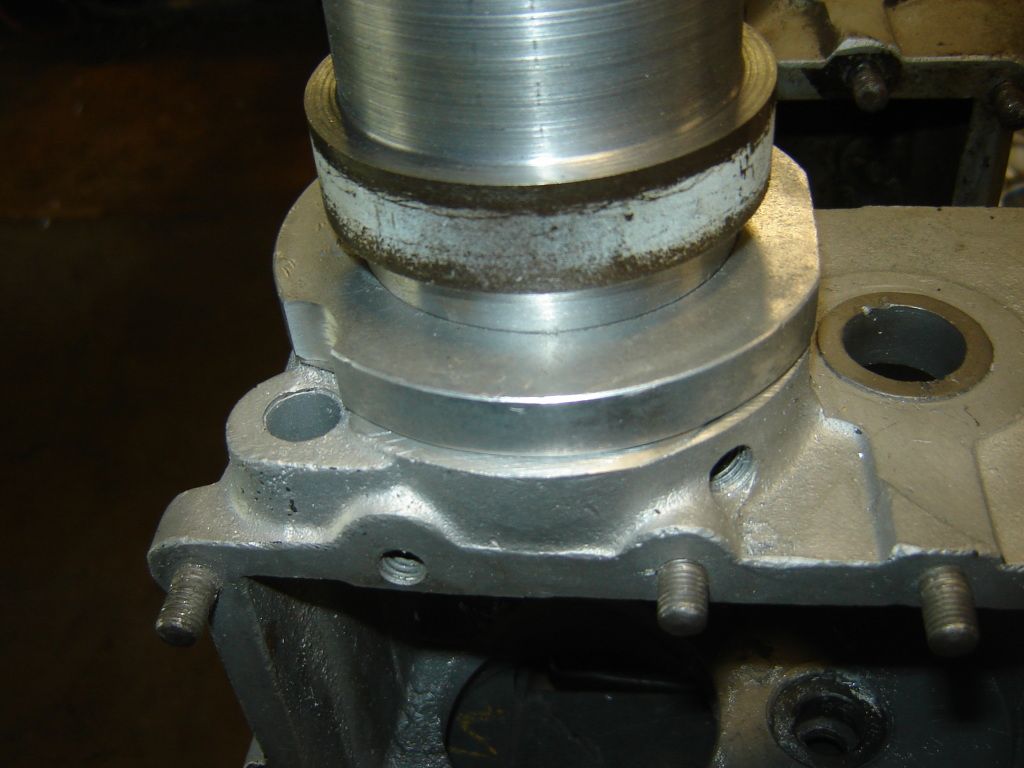

I dressed to off clean with a fine grit sander and should be ready to make the rod next.

Jerry

I made a threaded insert that accepts a WL type thread. and pressed it in to the stem. I then proceeded to tig weld it in to the top of the neck.

I dressed to off clean with a fine grit sander and should be ready to make the rod next.

Jerry

[/IMG]

[/IMG]

Comment