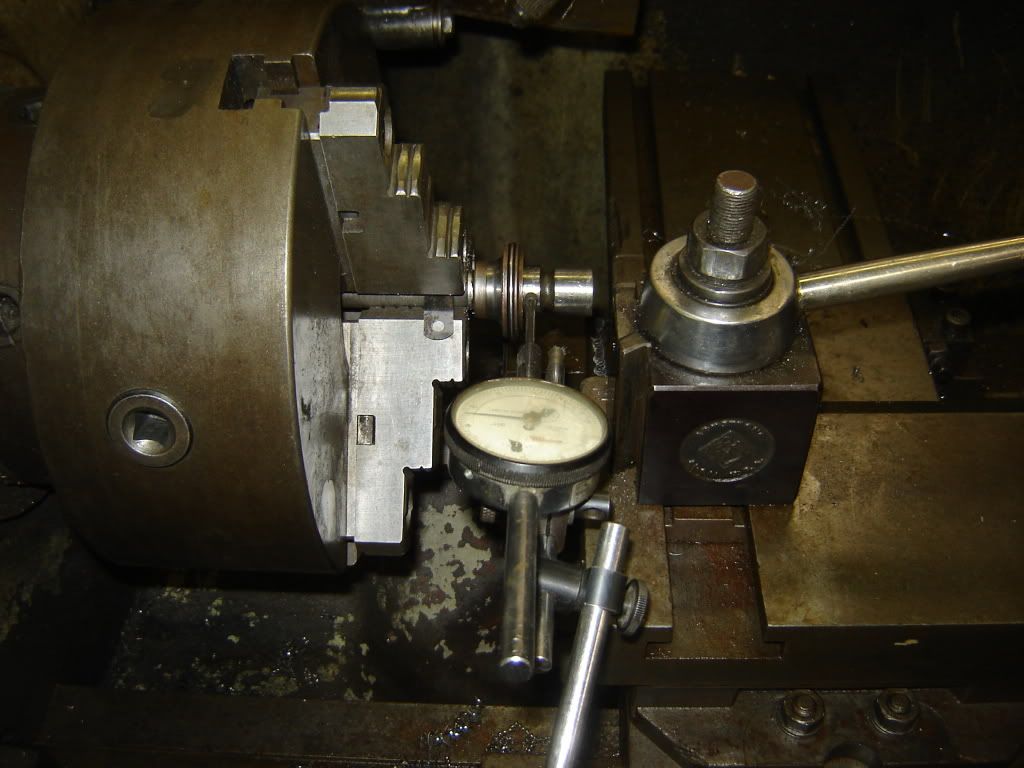

I have been working on the front fork the last couple of nights and got most of the problems ironed out. I needed to straighten the upper tube where I removed the dent the last time I posted pictures. I took a couple of 1" split clamp collars and turned them in a lathe to fit the upper rear leg.

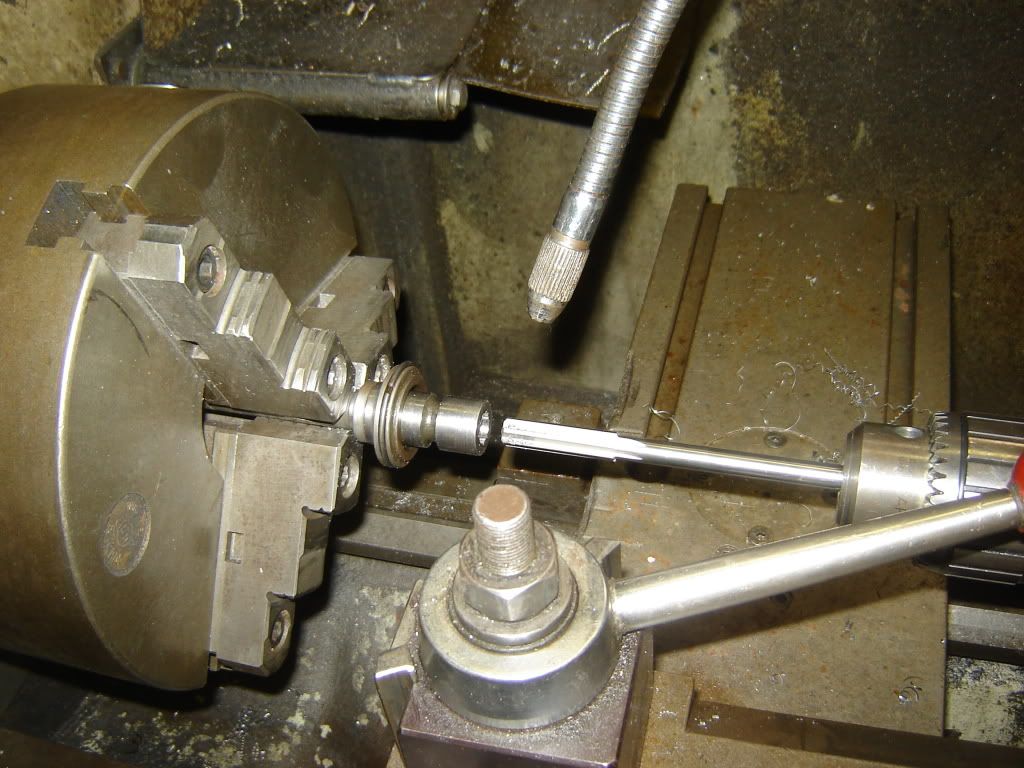

Then I turned down a shaft so that it fit in top of the tube. The collar with the bigger hole I welded to a piece of box tubing that I clamped down to my table. The tube with the smaller hole I clamped down on the upper tube where it is split to allow the top clamp to pinch down on the 2 handle bar stems. The I placed a short bottle jack under each end of my setup. The jack on the lower leg was used merely as a convenient adjustable block.

I then proceeded to heat the bent area to a soft red and pumped up the jack on the right until it aligned straight visually. I left every thing as was until it was cool to the touch. I then let the pressure off the jack and it bent back part of the way so I repeated the whole process and this time I got it about as good as I could have ever expected.

Jerry

Then I turned down a shaft so that it fit in top of the tube. The collar with the bigger hole I welded to a piece of box tubing that I clamped down to my table. The tube with the smaller hole I clamped down on the upper tube where it is split to allow the top clamp to pinch down on the 2 handle bar stems. The I placed a short bottle jack under each end of my setup. The jack on the lower leg was used merely as a convenient adjustable block.

I then proceeded to heat the bent area to a soft red and pumped up the jack on the right until it aligned straight visually. I left every thing as was until it was cool to the touch. I then let the pressure off the jack and it bent back part of the way so I repeated the whole process and this time I got it about as good as I could have ever expected.

Jerry

Comment