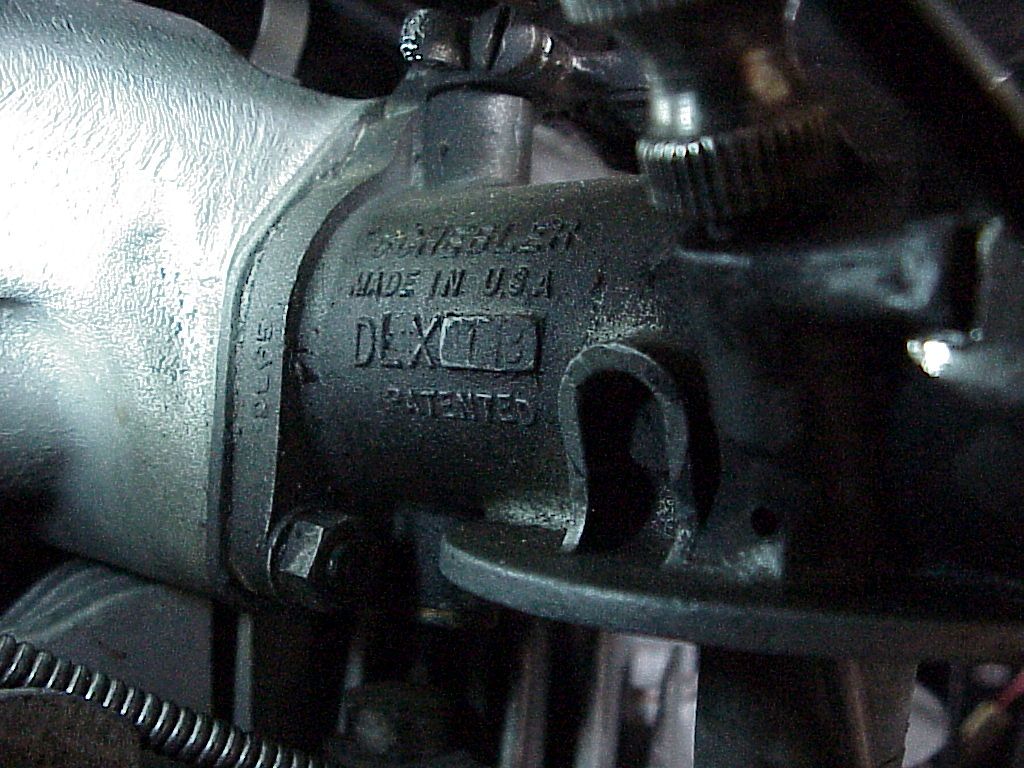

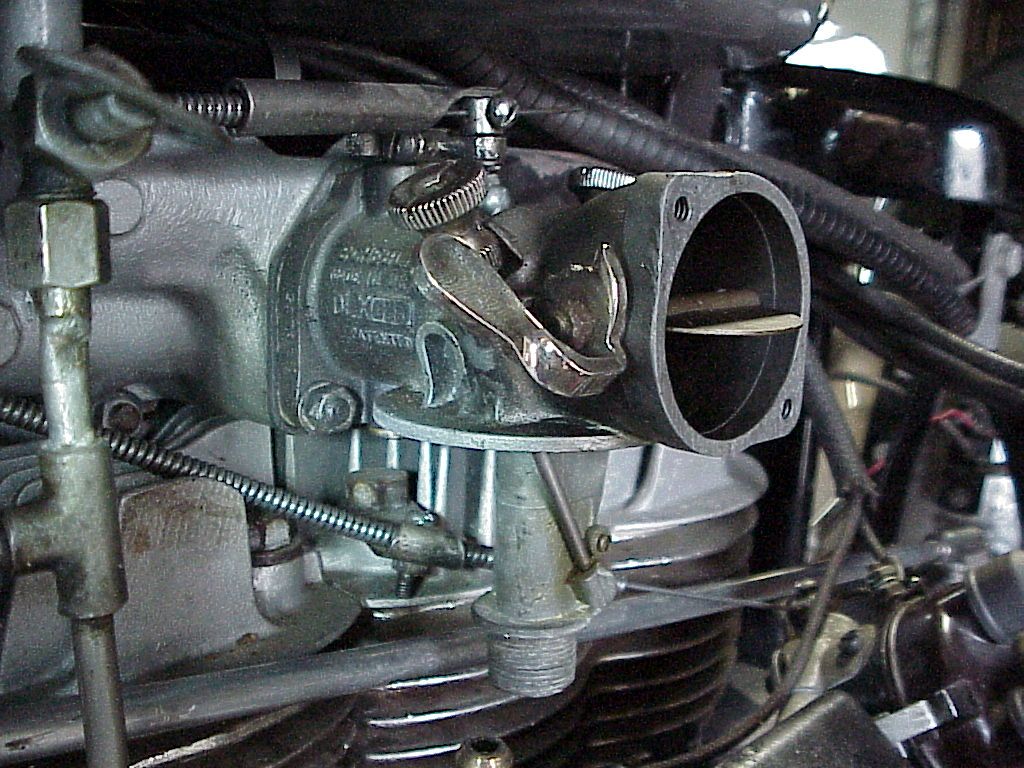

Thanks for the quick reply. I was a machinist in a former life so I understand your points well. Although I must admit that I did not know you could TIG weld Zamac, which is what I believe this are made from.

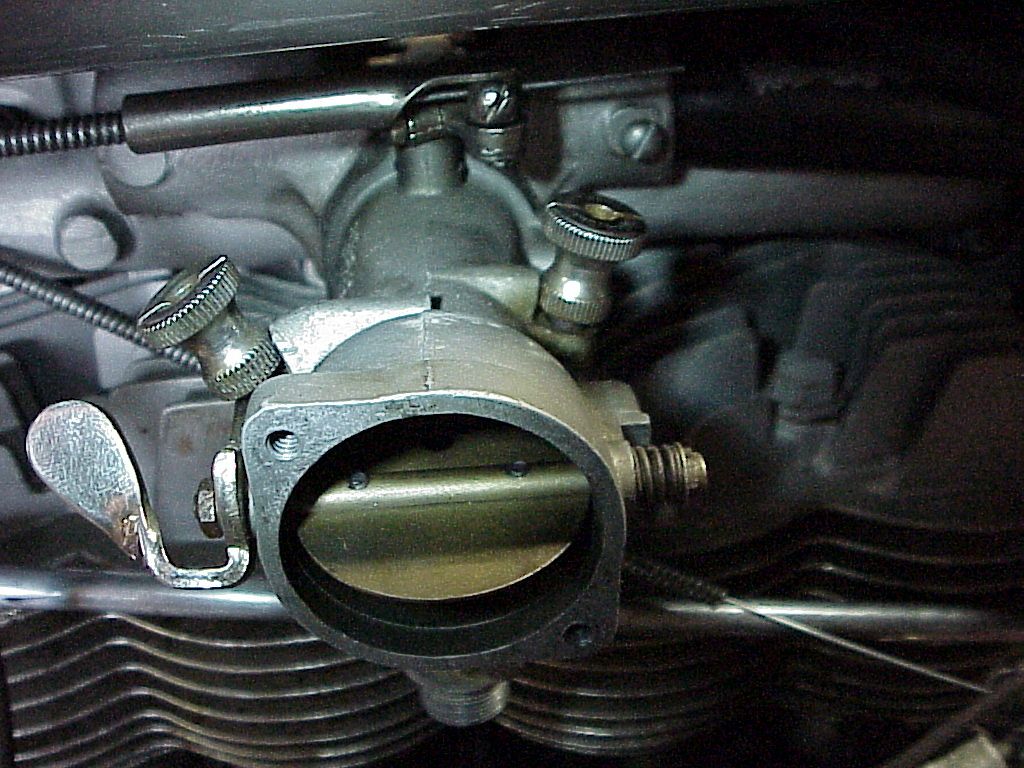

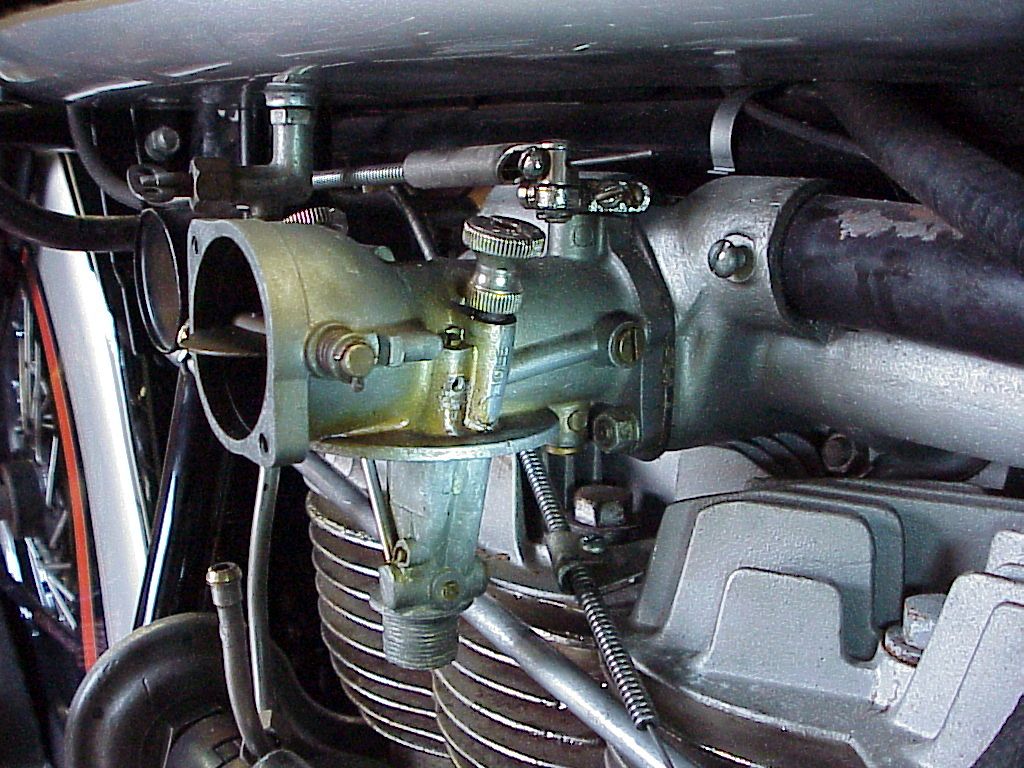

I have spoken to a gent that makes new floats from modern milspec materials that are not affected by today's fuels. Although that could very well be what is already in the carb since the bike was restored about 6 years ago. Guess I'll find out when I take it apart to stop the drooling. Like that term better than overflow. Fits the age of the bike. Fire is a scary thought and my first when I noticed onto what the fuel was drooling that first day. No battery in the bike at the time.

Thanks again.

regards,

Rob

I have spoken to a gent that makes new floats from modern milspec materials that are not affected by today's fuels. Although that could very well be what is already in the carb since the bike was restored about 6 years ago. Guess I'll find out when I take it apart to stop the drooling. Like that term better than overflow. Fits the age of the bike. Fire is a scary thought and my first when I noticed onto what the fuel was drooling that first day. No battery in the bike at the time.

Thanks again.

regards,

Rob

Comment