It looks to be an affect of the extrusion process.

Announcement

Collapse

No announcement yet.

The making of a 1936 Knucklehead springer front end

Collapse

X

-

I’ve held off giving my view on this subject till now. Let’s get real here. The motor company was in the business of making motorcycles. Not some exotic bullshit. These drunken Pollacks probably had to put together four of these and hour are they were unemployed. The lower legs and top legs were both casted. Did you think for one minute that Harley had some magical wan that made tubes reduce size laterally. You can cast chrome molly just the same way you can cast 1018 carbon steel. The finish is dependent upon what type of sand you’re using and how tight it’s packed. The design was great, top tube fit into the bottom tube in the braces. Insert reinforcement sleeve and you’re done. Now let’s talk about jigs. They didn’t have pneumatic or electrical servo motors. What they did have were simple screw vices that locked all this crap together prior to putting it in the furnace. How much you want to bet that one of the vices lost its holding pad and the screw was allowed to in dent the side of the fork tube until one of these brain surgeons caught it. Harley was cheap. Dent or not that fork want on the shelf. Do you think for one minute that the consumer ever gave a damm. Extrusion process is for aluminum. Bob L

Comment

-

The '36 E shift lever was swaged tube. I see no reason why the legs weren't swaged. A cast part would have a texture on it and be brittle. Sadly AMF tossed all the documents telling how to make parts.Be sure to visit;

http://www.vintageamericanmotorcycles.com/main.php

Be sure to register at the site so you can see large images.

Also be sure to visit http://www.caimag.com/forum/

Comment

-

Bob L, Do you really think they were sand cast? The rear leg is hollow correct? With the shape of the leg how was the form removed from the inside of the leg after casting? Swedged not cast IMHO. I could also see a form die being used, but not cast, when a casting is not solid you need someway to remove the inside core. Bob#6738Bob Rice #6738

Comment

-

Bob, you beat me to my post. Chris, you are most likely right about the swaging thing. I have a bad habit of looking at everything in today’s labor market and saying to myself, why would anyone in their right mind go through all that labor to make a radius rod but the reality is labor at the time was dirt cheap. I’m sticking to my theory on the dent thou. It makes too much sense. Bob L

Comment

-

Robert L., Sorry but you are talking out of the wrong orfice. The tubes are swaged. Harley explains the manufacturing process on page 12 of the "Lets Visit the Harley Davidson Factory". Maybe someone could scan it and post it. The short story is that they begin as 1 1/2" plain straight tubes. They speak of the swaging machine steps and dies.

Comment

-

I recall reading an article about the reintroduction of the springer back in the 90s. The article said H-D brought in an old employee who had swaged springer tubing for many years. Apparently, there was a great deal of technique involved in getting them right and that aspects of the process could not be plainly documented. That is not very hard to imagine considering you don't make a leg with one simple blow of a forging die.Eric Smith

AMCA #886

Comment

-

Originally posted by Jerry Wieland View PostThe brake anchor needs to have the weld disappear and be brazed. I have not had much luck trying to braze with a torch what HD brazed with a furnace. It is hard to get enough heat into the fork to get the braze to fuse without getting too much heat. So what I do is dress the weld until it no longer looks like a weld. I have had a fair amount of practice doing this because over the years I have fixed quite a few Indian frames that had 'slipped joints'. The late Indian frames were very poorly brazed and it is not uncommon to have a joint pull apart. I would remove the tube and then because I no luck with brazing the big bulky Indian castings, I would weld them and then have to dress them back to appear not welded.

Before

After

Jerry,

I know you ground the weld down to make the brake anchor look like it was brazed on but you will also have to modify the length of the lug with the hole in it. The early ones do not stick out as far from the rear leg as the later ones do. This was changed when the locking tab was introduced and the early cotter pin style brake shackle stud was done away with.

Comment

-

Matt Thanks for the heads up. I thought I checked it out real good but I will double check and see. JerryOriginally posted by Matt McManus View PostJerry,

I know you ground the weld down to make the brake anchor look like it was brazed on but you will also have to modify the length of the lug with the hole in it. The early ones do not stick out as far from the rear leg as the later ones do. This was changed when the locking tab was introduced and the early cotter pin style brake shackle stud was done away with.

Comment

-

Dan There are at least 5 different upper spring perches used on the 1936 and up springer.Originally posted by DANPATCH View PostHow do you tell the difference in the the first reinforcing of the spring perch that occurred for sure by 1943. Thanks for your time

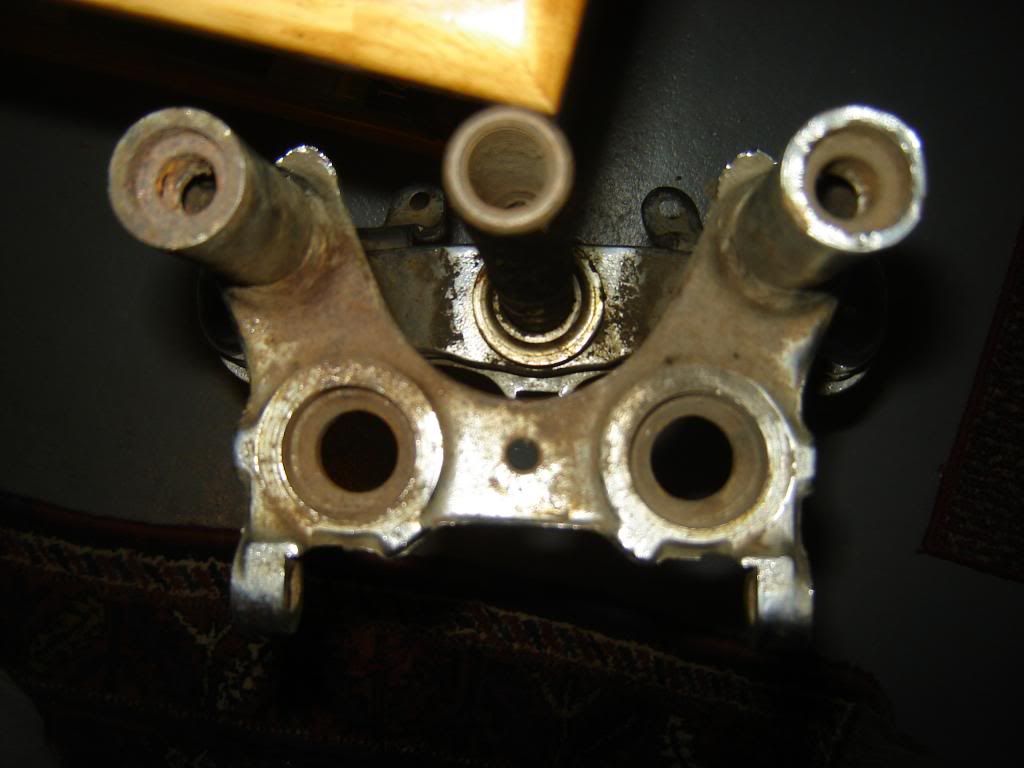

Here is the first version used from 1936 until sometime in 1938.

Then this second version went from later 1938 until sometime in the early 1940's. I really feel bad about this because I had it all sorted out at one time by getting JWL to look at his original paint bikes but I apparently did not write it down. For sure it is in use until probably early 1942. Grease zerk bosses have been moved to the outside.

Dan, this is the third version of springer perch that was in use by 1943. I hi-lighted the area of the reinforcement.

Now when they went to this next one, the fourth version, I do not know but I suspect some time around 1945/46. If anybody can help me out on this one I would appreciate it. The area behind the rod guide hole is now reinforced plus the lip around the hole is beefier but the inside zerk bosses still exist.

This fifth version I believe came out on the very last of the in-line springers in 1946. All offset springers that I have ever seen have this one. Notice that no evidence of the inside zerk bosses exists anymore.

JerryLast edited by Jerry Wieland; 01-04-2014, 09:10 PM.

Comment

-

Now a days i think they call it lost core casting, sand is glued in a form then inserted in place for casting. After metal is solid part is vibrated and glued sand is reduced again to sand. Heads on automobile are done this way now, intake and exhaust ports and runners look like a spider when inserted in machine. I agree Swedged.Originally posted by BigLakeBob View PostBob L, Do you really think they were sand cast? The rear leg is hollow correct? With the shape of the leg how was the form removed from the inside of the leg after casting? Swedged not cast IMHO. I could also see a form die being used, but not cast, when a casting is not solid you need someway to remove the inside core. Bob#6738

And yes some of us are Polish......Last edited by knuckcrazy; 01-05-2014, 12:35 AM.

Comment

Comment