The brake anchor needs to have the weld disappear and be brazed. I have not had much luck trying to braze with a torch what HD brazed with a furnace. It is hard to get enough heat into the fork to get the braze to fuse without getting too much heat. So what I do is dress the weld until it no longer looks like a weld. I have had a fair amount of practice doing this because over the years I have fixed quite a few Indian frames that had 'slipped joints'. The late Indian frames were very poorly brazed and it is not uncommon to have a joint pull apart. I would remove the tube and then because I no luck with brazing the big bulky Indian castings, I would weld them and then have to dress them back to appear not welded.

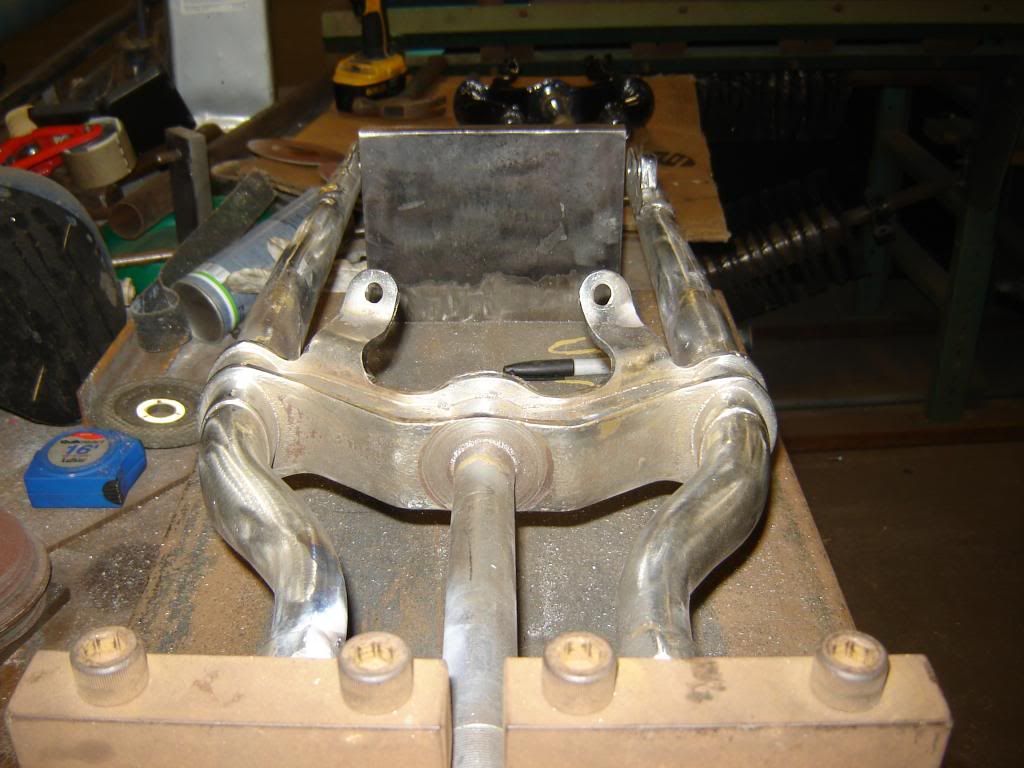

Before

After

Before

After

Comment