jerry you can just pop in sealed bearings. i have heard guys say" when people rebuild jd trannys they over tighten the main shaft trying to make the copper disk seal in the oil. they claim this makes to much heat in the gear box.

Announcement

Collapse

No announcement yet.

1925 JD Cannonball Bike

Collapse

X

-

-

Robs right, use a 6208 2RS and a 6304 2RS bearing

On 26 and later gearboxes they go straight in.

I'm not sure about 1925 but 1924 and earlier boxes you have to grind some of the shoulder back on the output gear to get your required clearance.

There's a lot of kiwis using this mod and it is trouble free and doesn't leak any oil.

I don't remove any of the seals from the bearings and use grease in the outer cover to lube the kickstart.Peter Thomson, a.k.a. Tommo

A.M.C.A. # 2777

Palmerston North, New Zealand.

Comment

-

Rob and Tommo Thanks for the heads up. I had noticed that on 2 of the transmission I took apart that they had a different bearing on the right side of the main shaft. It had the same id/od as OEM but was approximately .060" wider.

Are these bearings sealed and do you leave the seals in ? I believe they ought to fit 1925 then also. The only difference I can see in a 25 tranny is that it still uses the old clutch release bearing and shifting lock - internals are the same.

JerryLast edited by Jerry Wieland; 05-27-2012, 01:57 PM.

Comment

-

I have been looking for the original seat T cross bar for awhile with no luck until a fellow JD enthusiast fronted me one that he had started on.

The stem is OEM and he made the cross shaft and sweated it in the stem. This is what the original one looked like and this is a seat that was loaned to me so I could copy it.

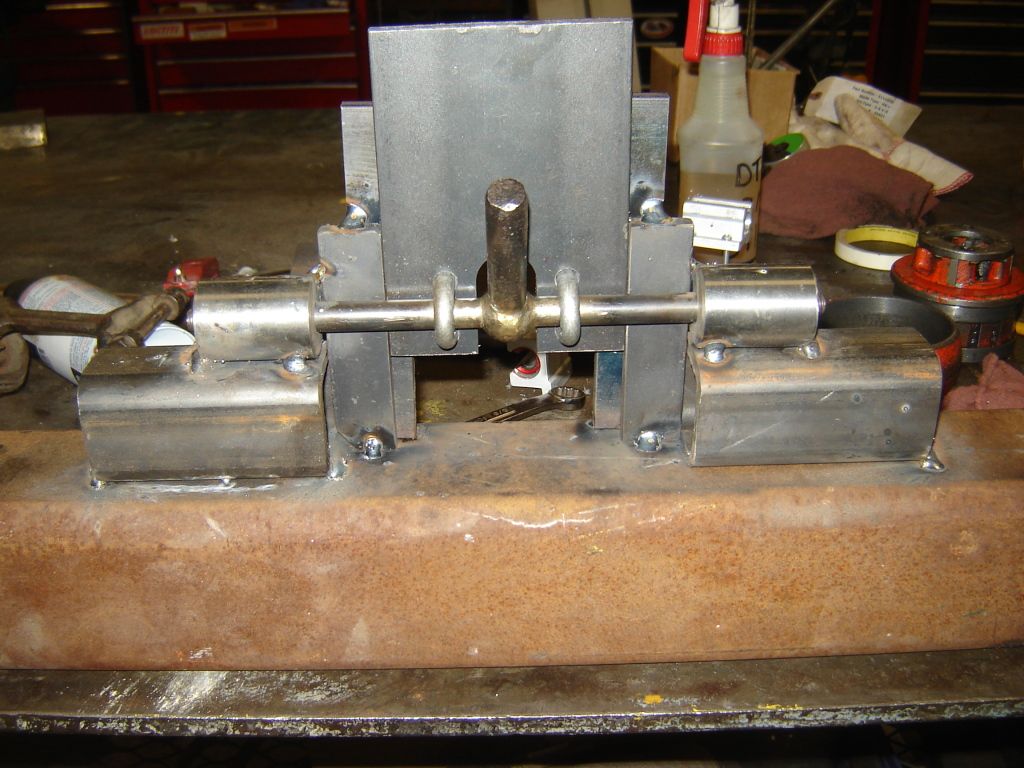

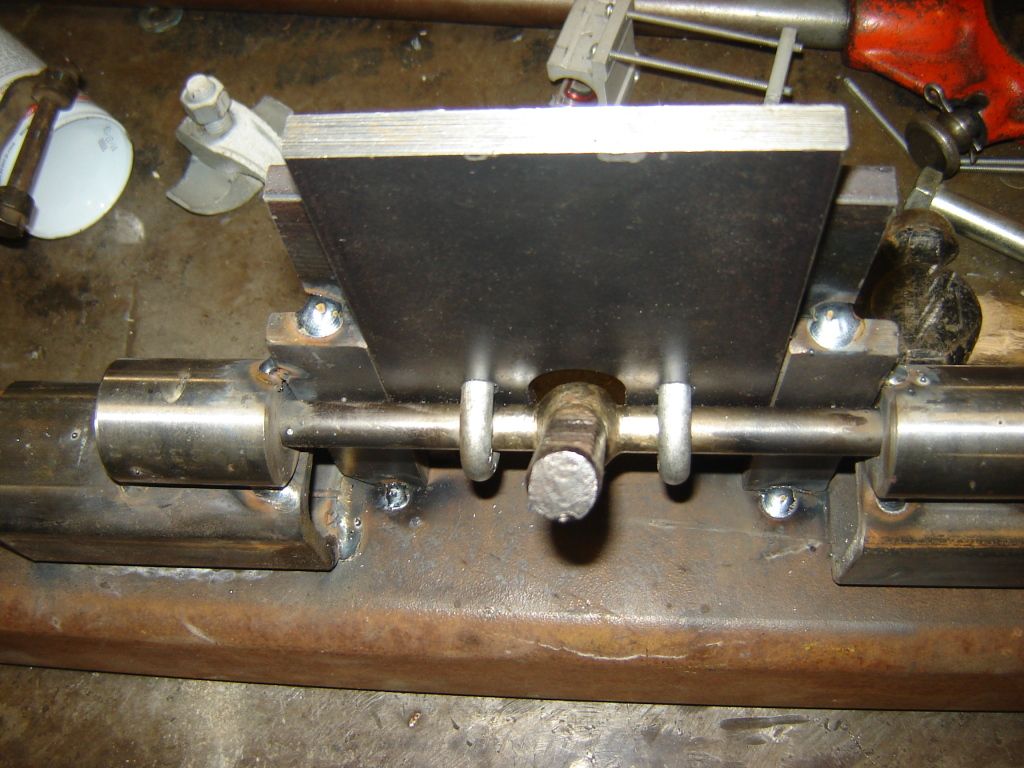

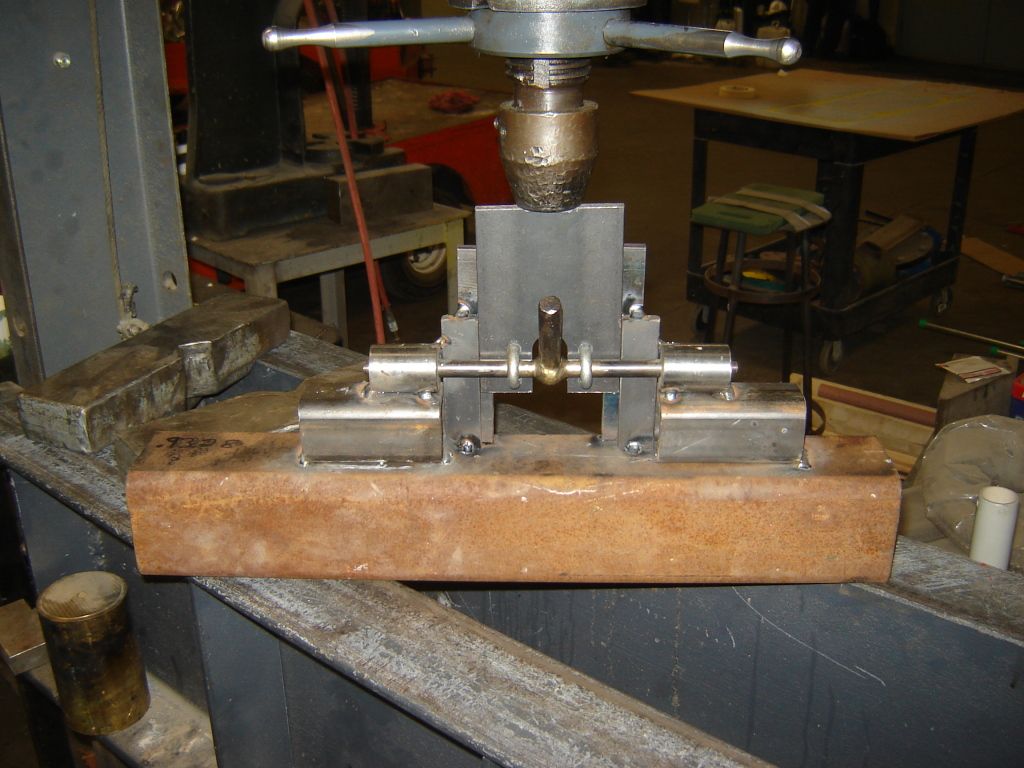

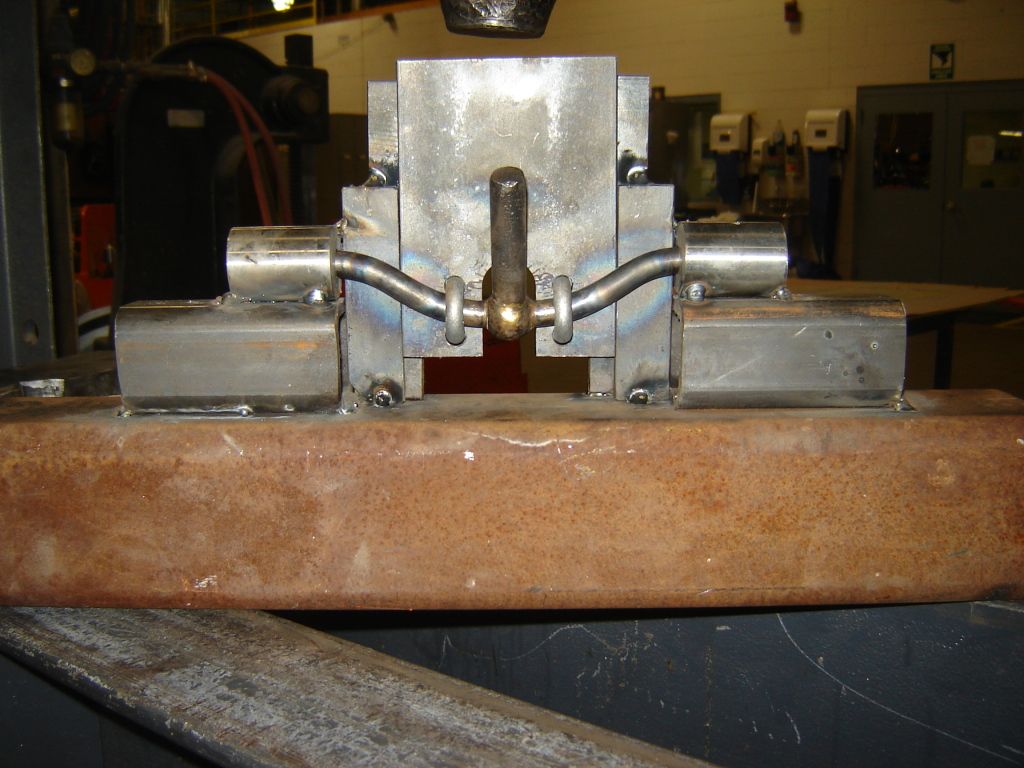

Today I made a fixture that put the bend in it. I haven't done a lot of this kind of work and it probably shows. The fixture was made to me a throw away because I do not have the time and no reason to make it reusable. I got to make it work the first time. I had about 4 hours in this whole situation.

Basically I turned a 1/2" hole in 2 spool shafts and welded them to a 4" x 4" steel tube and spaced it up with smaller square tube. The rest is just a plate that u bolted to the seat crossbar and held it at the exact angle I needed to replicate the original one. The rest of the steel is just a guide plate so that it stays firmly on track when I push on it.

The press is a 80 ton manual hydraulic press and this is child's play for it. I did have to use a little heat as I expected to get the bend how I wanted it. This is not ideal but I did not have one to practice on.

JerryLast edited by Jerry Wieland; 05-26-2012, 10:25 PM.

Comment

-

I am also starting to think of chains, sprockets and gear ratios. Anybody have any experience with this. The bike needs to run comfortably at 55/60 mph but still have decent low end power.

I would appreciate any input on this - even negative because knowing what not to use is as important as what to use.

Jerry

Comment

-

Jerry

Damned ingenious!

I'm really enjoying this thread.

As for gearing on the J Models. I can tell you what I'm running.

I am geared as tall as I believe is possible with these machines.

18 tooth motor sprocket

28 tooth countershaft sprocket

40 tooth wheel sprocket.

I experimented around originally with 44 and 48 tooth wheel sprockets and was running a 17 tooth motor sprocket on my 28 with good results. But I really like the use of the full 1-2-3 range of the trannsmission running as tall as possible. And I have no problems starting out in low despite being a 200 lb+ guy. The problems with trying to run 55-60 with a J model is your out of chassis/suspension and brakes around 40 mph!

Scott

Comment

-

I'd paint it with black high temp exhaust paint and cook it in a powdercoat oven to cure it.

Mark MasaMark Masa

www.linkcycles.com

Comment

-

I have had problems with my internet service provider and have not been able to follow this site for a year. Problems now resolved, I have read this thread from beginning to end this morning. Your dedicated effort to pass along this information is very educational and informative. I know it must take a lot of your time to take all of those pictures and write the comments. Having just finished a 10 year restoration of a 1932 Packard I am very interested in how restoration problems are solved. You're to be commended for passing along these problem solving solutions to the rest of us. I only wish I were as good at this as you are but hopefully one can learn. I'll be able to follow the rest of your work on a daily basis now.

thanks,

Howard

Comment

-

Discard them if you leave both seals on each bearing but put them in if you remove the inner seal on the bearing.

I leave both seals on and discard the brass slingers.Peter Thomson, a.k.a. Tommo

A.M.C.A. # 2777

Palmerston North, New Zealand.

Comment

Comment