I can't really tell the important details, Harry,..

But it looks more "real" than a TEDD/eBay offering.

(Personally, I would re-texture it. Like a signature.)

I usually ground the top to 'flat' first, and then chucked it up square to skim the bowlnut and floatvalve decks on the bottom.

(Schebler shown in attachment.)

It used to take fifteen minutes ($15), but if I ever take any more work, I'll charge post-pandemic price!

....Cotten

PS: Can you caliper from the top of the bowl deck to the centerline of the pivot screw?

It should be about a half an inch, or it messes with the geometry. Some of the Euro reproductions missed by a kilometer.

Announcement

Collapse

No announcement yet.

Linkert M741-1 rebuild

Collapse

X

-

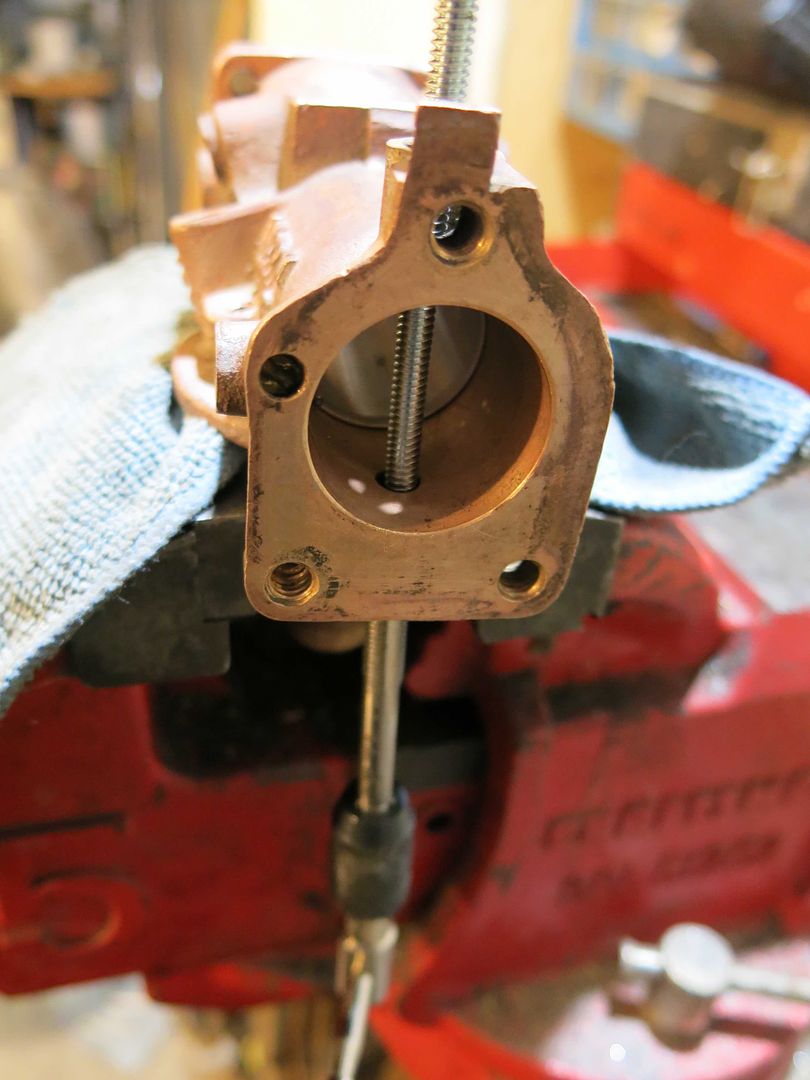

while waiting for a reamer that I ordered to arrive, I tried out the new reproduction bowl for fit. Nice bowl, but it didn't sit flat against the base:

Maybe it was cast a little too thick? But the bowl was hitting the carburetor casting where the lower bushing for the throttle shaft is:

Rather than alter the bowl, and because it wouldn't take removing very much material, I decided to use the Dremel and remove just a little from the carburetor casting to allow the bowl to sit flat:

Leave a comment:

-

Everybody does it different, Harry!

I use a ground quarter-inch rod to align both bushings, and have pucks to press them in gently. The pucks are also counter-bored to leave ~.015" or so exposed. Pressing in too far often puckers the end of the bushing at the bottom of its bore, and Monel is not really friendly to reamers. Sometimes I must line-hone them.

This pucker often gives a false fit, scarring the shaft.

....Cotten

PS: The only literature mentioning Monel that I can find quickly is the 1930 Indian catalog for Scheblers.Last edited by T. Cotten; 04-25-2020, 01:14 PM.

Leave a comment:

-

Thanks Mick and Steve, I’m sure that’s the right call! ...ironically I will probably have the correct reamer come in the mail at about the same time I would have finished up with the sandpaper :-)

Leave a comment:

-

i would second what Mick says. if the circumference is irregular top to bottom its an air leak. i also note a number of these carb parts sellers make the bushes out of steel, one of the highly respected old timers i mentored under told me they were made of Monel metal and i believe there is documentation to back that up. monel metal, as i understood it, wore better in the application of the rotating shaft. Waiting for Tom Cotten to jump on board.

Leave a comment:

-

Harry,

I have used the sandpaper on a stick often for various situations, including carby bushes.

You need to use a full width "stick and paper" to ensure the top and bottom bushes are lined up. The nature of the sandpaper means the backing material is flexible. This will "Bell" the entrance and exit of any bushes you ream with this setup.

I find a full width hand reamer is the best tool for this job. I prefer an adjustable hand reamer that is wide enough to ream the top and bottom bushes at the same time. The clearance of these bushes can have an influence on how well an expensive motor runs, so i consider them a cheap tool to have.

Leave a comment:

-

So now onto the new bushings. I put them in the freezer yesterday, though I'm not certain it made any difference? I took a wooden dowel and turned down the end of it to fit inside the bushing, then with the bushing on the dowel I inserted it into the casting and tapped it in place:

They both went in flush without too much effort, half a dozen light taps with a small 8oz hammer:

So now I have to figure out how to ream these bushings so that the throttle shaft is tight, but not too tight! I have a few hand reamers, but not one that small, I was thinking of using another dowel wrapped in 400 grit sandpaper to see if that does it. Ideas welcome!Last edited by pisten-bully; 04-24-2020, 08:45 PM.

Leave a comment:

-

Parts showed up yesterday, yes they were expensive:

First thing I did was to remove the old throttle shaft bushings, there was actually little play in the throttle shaft but all the literature informs you that worn throttle shaft bushings are to be expected, so why go through a rebuild and NOT replace the bushings? I used a 7mm tap, mostly because I've never used it before and it threaded into the bushings without going too far:

I tapped the bushing with the 7mm threading tap, and then from the other side I used a thin threaded rod to tap on the threaded tap with a light hammer to to push out the bushing, worked like a charm:

Last edited by pisten-bully; 04-24-2020, 08:52 PM.

Last edited by pisten-bully; 04-24-2020, 08:52 PM.

Leave a comment:

-

Replacing a spigot is routine, Harry!

....Cotten

PS: What have you got to lose?Attached FilesLast edited by T. Cotten; 04-15-2020, 02:52 PM.

Leave a comment:

-

The one that was in there:

It has a fifth hole in the stem, but that hole is not round and I don't think it's meant to be there!

Leave a comment:

-

I've changed my mind, Harry!

The M441 had a 'Bonne' nozzle, like on the right in the attachment;

M741(-1) shown in the middle, and a DLX63 on the left.

Note not also the difference in holes, but how high the top holes are.

Although anything might "run", only trial and error can tell us what is best.

(It would be easy to put another #57 hole in the 741.)

....Cotten

PS: The DLX and 741 have a #28 bore; The Bonne has a #28 spigot, but the body bore is a tight #33,

So who knows how it would run!Attached FilesLast edited by T. Cotten; 04-15-2020, 01:40 PM.

Leave a comment:

-

...Greer's will send me a venturi for an M441 ('41-'42 Indian Four), it's .816 i.d. and Todd says it will fit... so that's good, thanks again!

Leave a comment:

Leave a comment: