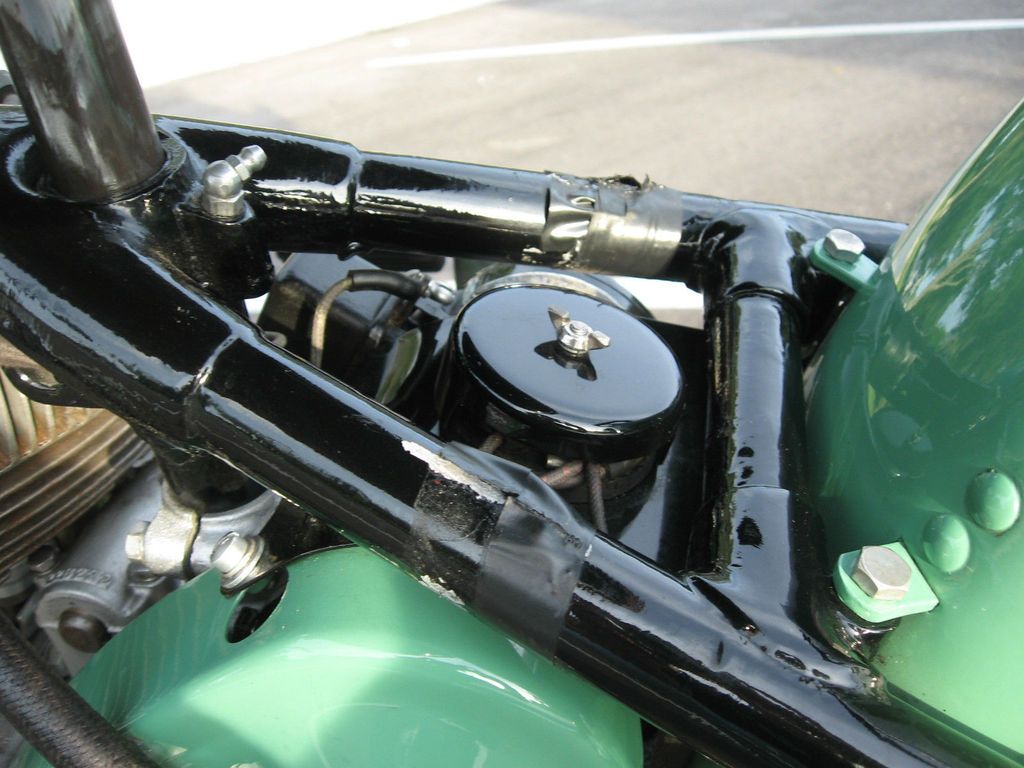

I have the 3 hole plate that has a gentle curve to it and is used to mount the round fuse block assembly with a single (special) pass-thru bolt and wing nut on top. I am not having any luck finding a good picture of where it connects too and what bolts are used. I think the back two holes connect to the underside of the frame just above the generator and I assume the other 3rd hole connects to the generator or something?

Does anyone have more information, perhaps a good picture or two of this location as well? Also would the plate be painted the same color as the bike tin or the frame?

Does anyone have more information, perhaps a good picture or two of this location as well? Also would the plate be painted the same color as the bike tin or the frame?

Comment