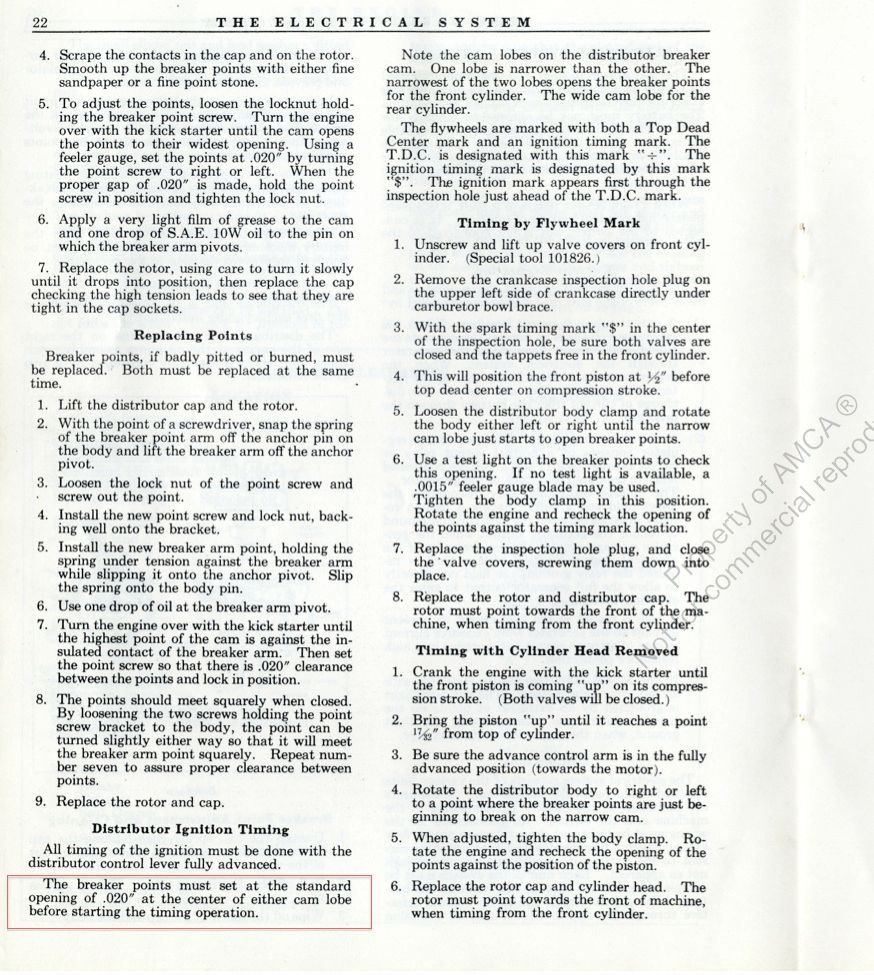

In process of rebuilding the distributor on a 48 as well as replacing the distributor driveshaft to eliminate rotational play. Prior to disassembling, I noticed the points would open .006 more on the small lobe compared to the large lobe. I thought it was probably due to wear because it appears to be the original shaft. After installing a new shaft from Greer, it also opens the points more on the small lobe but only about .004 more. This leads me to believe the variation is designed in for a reason but it doesn't seem right and my manuals don't say anything about it. Is this normal?

Thanks

Thanks

Comment