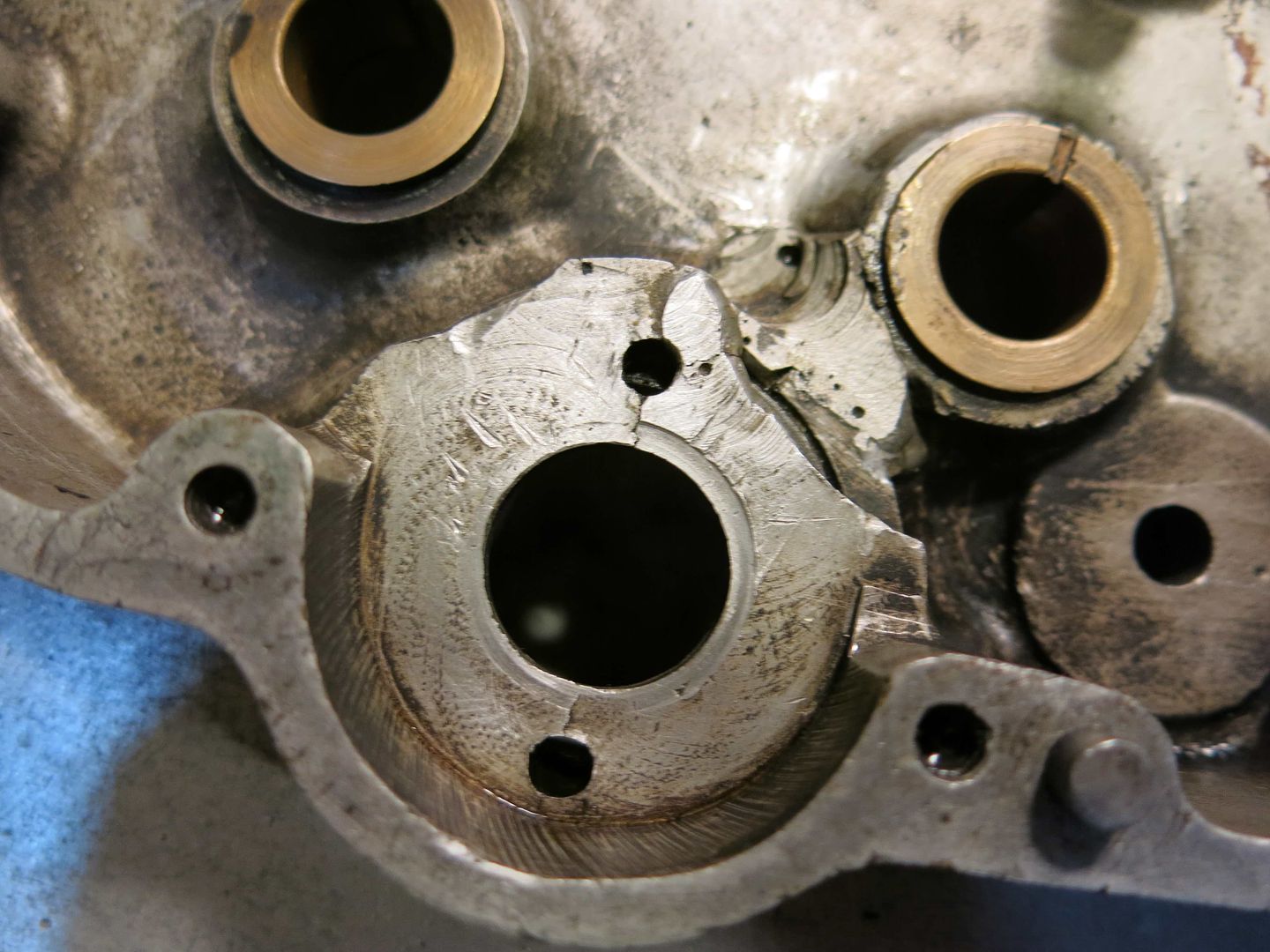

I wish I could smell the welds, Harry!

Can you scrape and listen to them and tell us what you might guess is the 'filler rod'?

Just getting something to stick is a trick.

And 'slag happens'.

....Cotten

Can you scrape and listen to them and tell us what you might guess is the 'filler rod'?

Just getting something to stick is a trick.

And 'slag happens'.

....Cotten

.jpg)

Comment