Iím am going to try and do a build thread, a crummy one probably, but maybe something I put up will show something helpful to someone elseÖ or to me!

My starting point is a frame purchased this summer with sheet metal and wheels from Ross in Manitoba, they look to be 1928 or 1929. And then thanks to a tip from Indianut I was able to purchase a 37ci motor from Norway, it is a 1930 motor. Iíve been casually collecting other parts (magneto, generator, generator drive, brake leverÖand not done yet) and Iíve started assessing what Iíve got and what I have to do get this Scout back on the road.

Hereí how things looked after receiving them:

this is actually a picture from Ross before I got the bike:

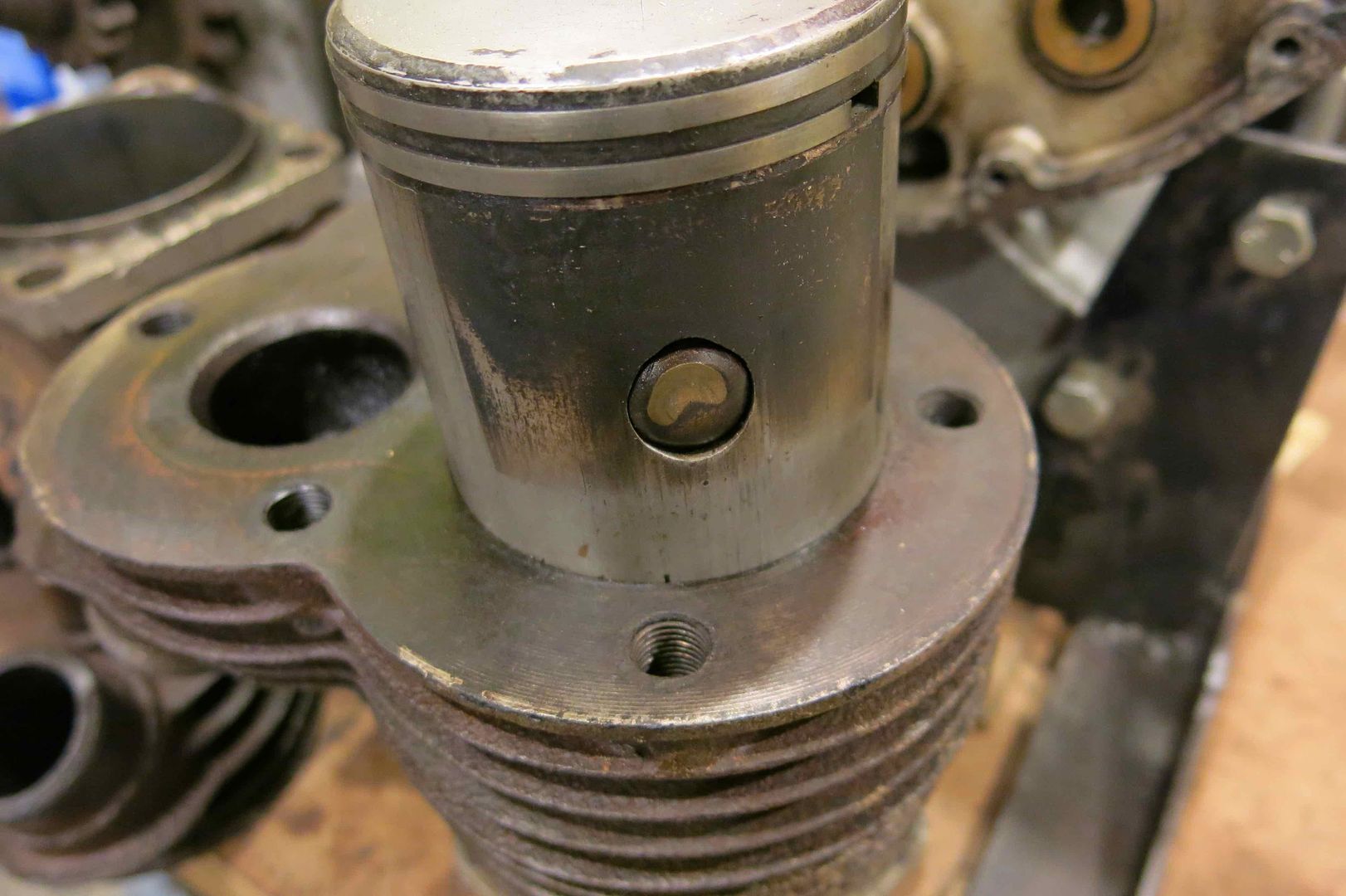

and the motor right after I got it:

My starting point is a frame purchased this summer with sheet metal and wheels from Ross in Manitoba, they look to be 1928 or 1929. And then thanks to a tip from Indianut I was able to purchase a 37ci motor from Norway, it is a 1930 motor. Iíve been casually collecting other parts (magneto, generator, generator drive, brake leverÖand not done yet) and Iíve started assessing what Iíve got and what I have to do get this Scout back on the road.

Hereí how things looked after receiving them:

this is actually a picture from Ross before I got the bike:

and the motor right after I got it:

Just like going up hill; you'll be half way to the top, look back, and be amazed at how far you have come. If I get a title for my free Honda, I'll be right there with you in new territory.

Just like going up hill; you'll be half way to the top, look back, and be amazed at how far you have come. If I get a title for my free Honda, I'll be right there with you in new territory.

Comment