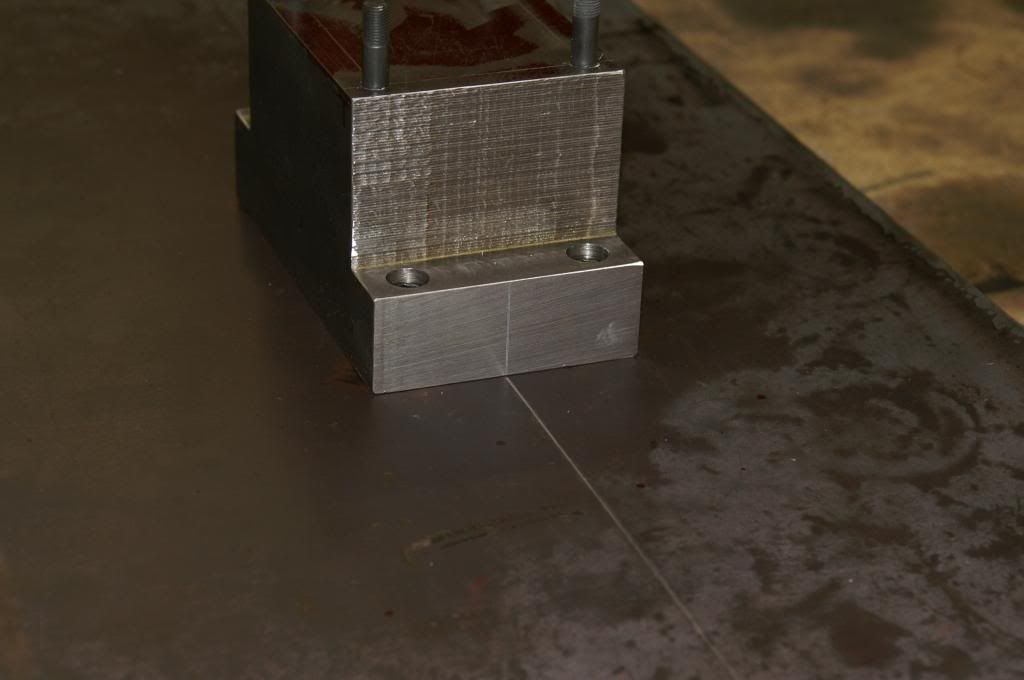

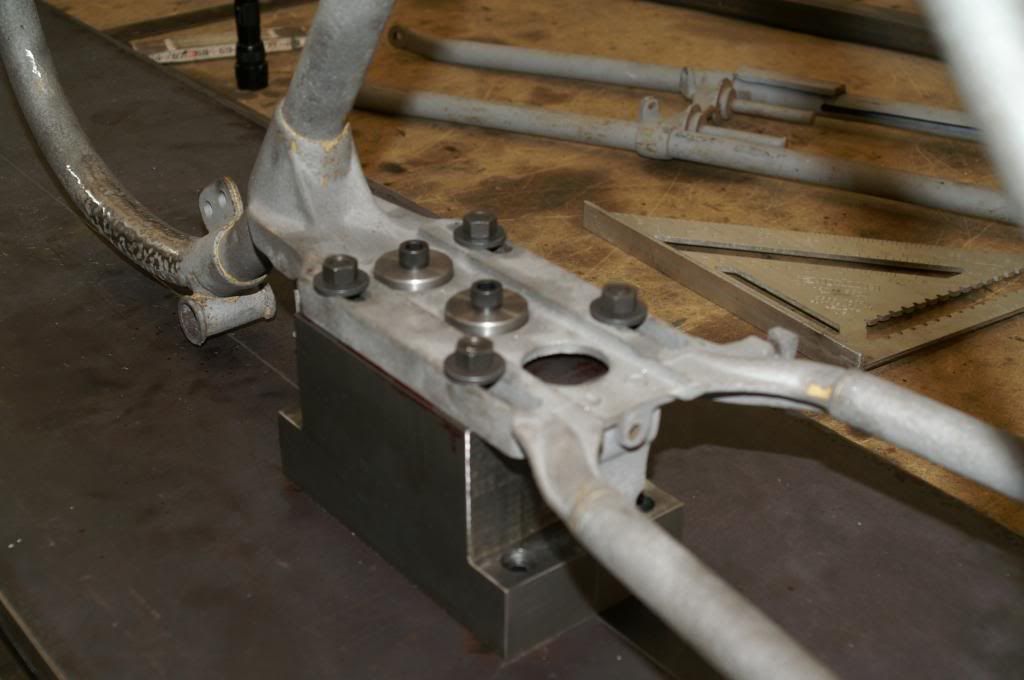

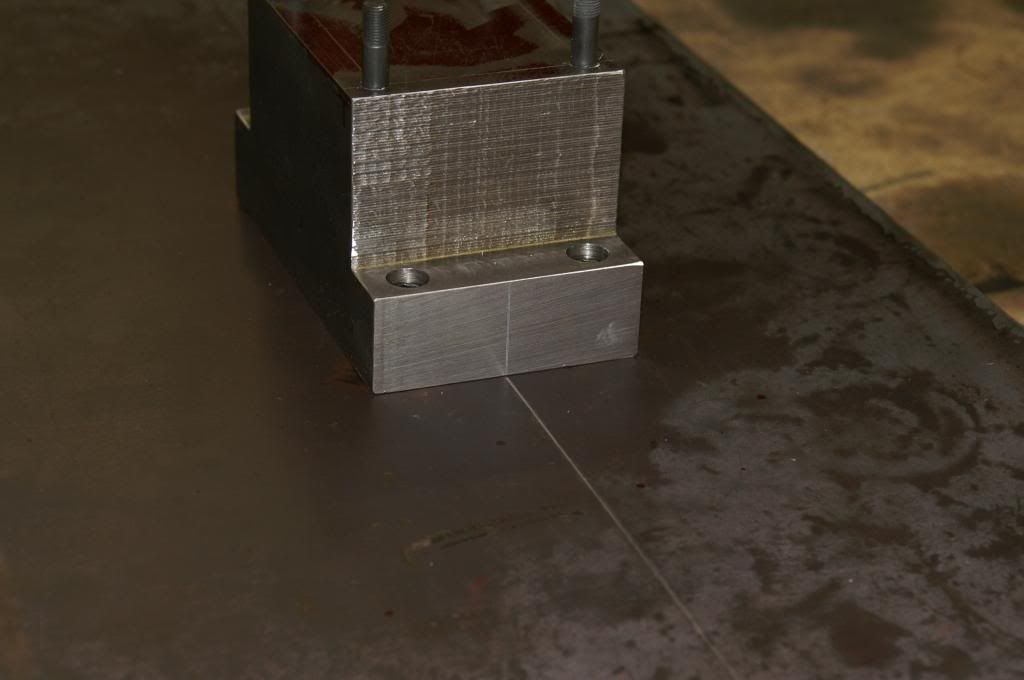

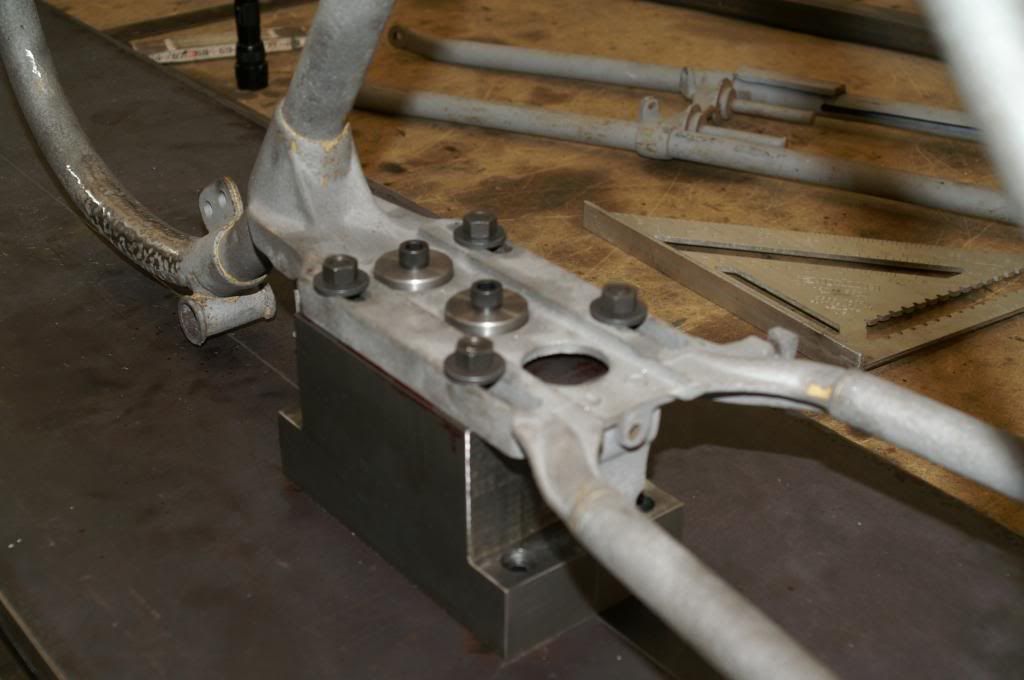

Good afternoon Ladies and Gentlemen figure I’d tune in and give ya an update on what’s going on with the little motorcycle that could! I ended up purchasing a 1”X16”X72” piece of flame cut plate to build a frame table. After putting it on the layout table on two blocks of wood - two days later it was sagging in the center, so it was off to buy some 2X2 square stock to beef it up. It took me two more weeks to score a piece of 6X6X7” bar to make the transmission mount but we’re getting there (man that was a lot of chips). The hockey pucks you see in the tranny plate are there so the rear axle plate carrier indexes properly every time I have to remove the frame. I tigged up the heavy pitting on the bottom tube today. So next week, let the straightening begin. I have one of those cheap ten ton bodywork ram sets that I think will suffice for the job. Keep in mind that I have no clue what I’m doing here. I’m winging it but in this type of scenario, Bob falls back on the number one rule. When in doubt, completely over kill. Over kill is a good thing for two reasons: first, it limits your chance of failure by 90% and second, nobody could ever accuse you of being lazy. Bob L

Comment