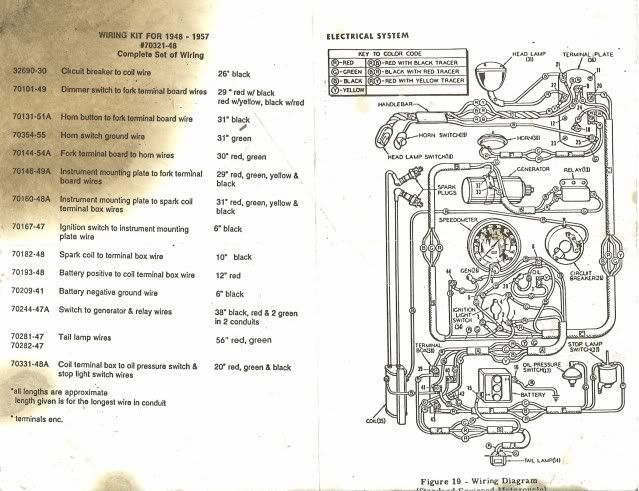

I didn't take very good pictures (in some cases) when I tore apart the '66, and all of the wiring was not stock...but. Have strung my new harness, made all of my terminal connections and there are two wiring Junctions on the dash plate according to the wiring diagram.

I have the old insulators and stuff, but I think I assumed they were ground connections at the time I took it all apart. Now, of course, I realize that they are hot connections. There was simply a bolt through a hole (probably a 10-32 bolt and a size 12 hole...) not much bigger than the bolt.. I have the insulating washers, but did they really just "center" the bolt so it did not touch the sides (not much clearance) and tighten 'r down? or was there some sort of insulating grommet. There are two of these junctions on the dash plate. On either side of the ignition switch...between it and the speedo.

Anyone have the secret? Am I missing parts or were there other mounting points? or did they really just center the bolt in the hole, tighten it down and hope it never shorted out?

Thanks,

Steve

I have the old insulators and stuff, but I think I assumed they were ground connections at the time I took it all apart. Now, of course, I realize that they are hot connections. There was simply a bolt through a hole (probably a 10-32 bolt and a size 12 hole...) not much bigger than the bolt.. I have the insulating washers, but did they really just "center" the bolt so it did not touch the sides (not much clearance) and tighten 'r down? or was there some sort of insulating grommet. There are two of these junctions on the dash plate. On either side of the ignition switch...between it and the speedo.

Anyone have the secret? Am I missing parts or were there other mounting points? or did they really just center the bolt in the hole, tighten it down and hope it never shorted out?

Thanks,

Steve

Comment