I've been getting my Chief ready for warmer weather, and one thing I do each off-season is to clean the carbon off the pistons and heads. This year I found a crack in the front head, first thinking it was a casting flaw. I had never noticed this before, but two years and 12,000 miles ago I had the front plug blow out of the hole during a ride, took the insert with it. I threaded it back in and got home, ordered a new insert and been riding it ever since, I even cleaned carbon off two times before I noticed this crack! Toyed with welding it up, but then I see it has cracked all the way through, and there are some other small cracks developing around the perimeter of the plug hole. I may have used this head for 12,000 miles or more with the crack, but I think it's time to replace it!

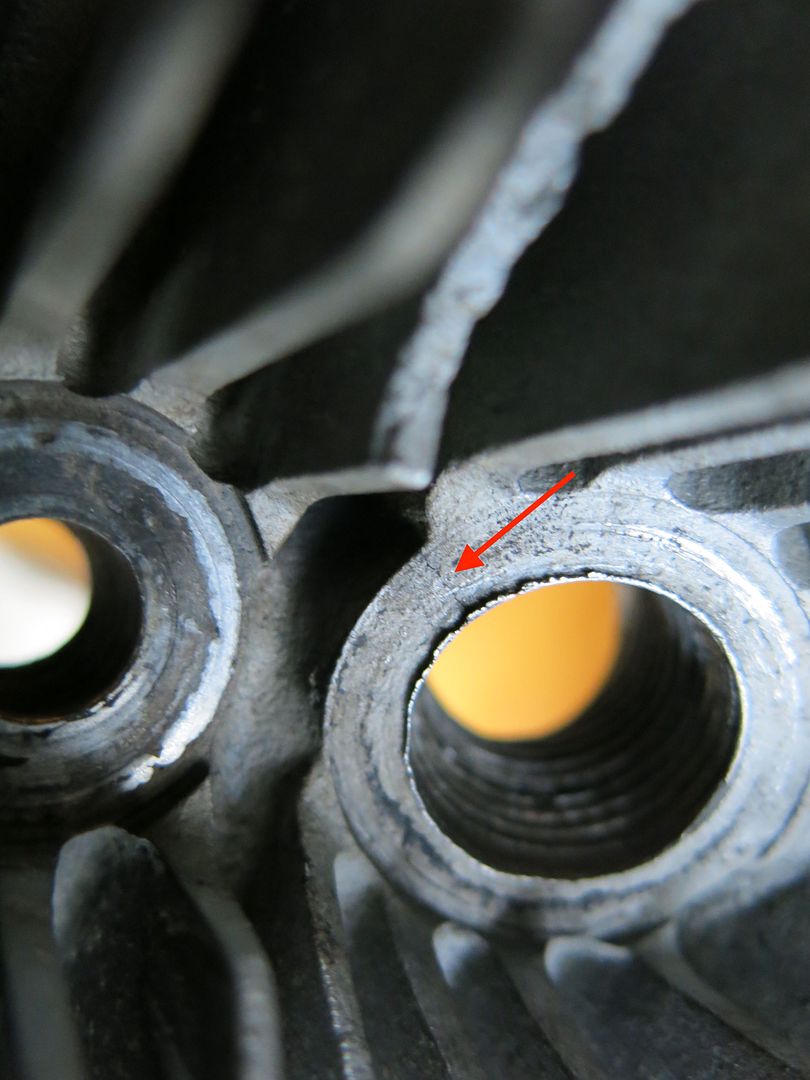

crack from the inside of the head:

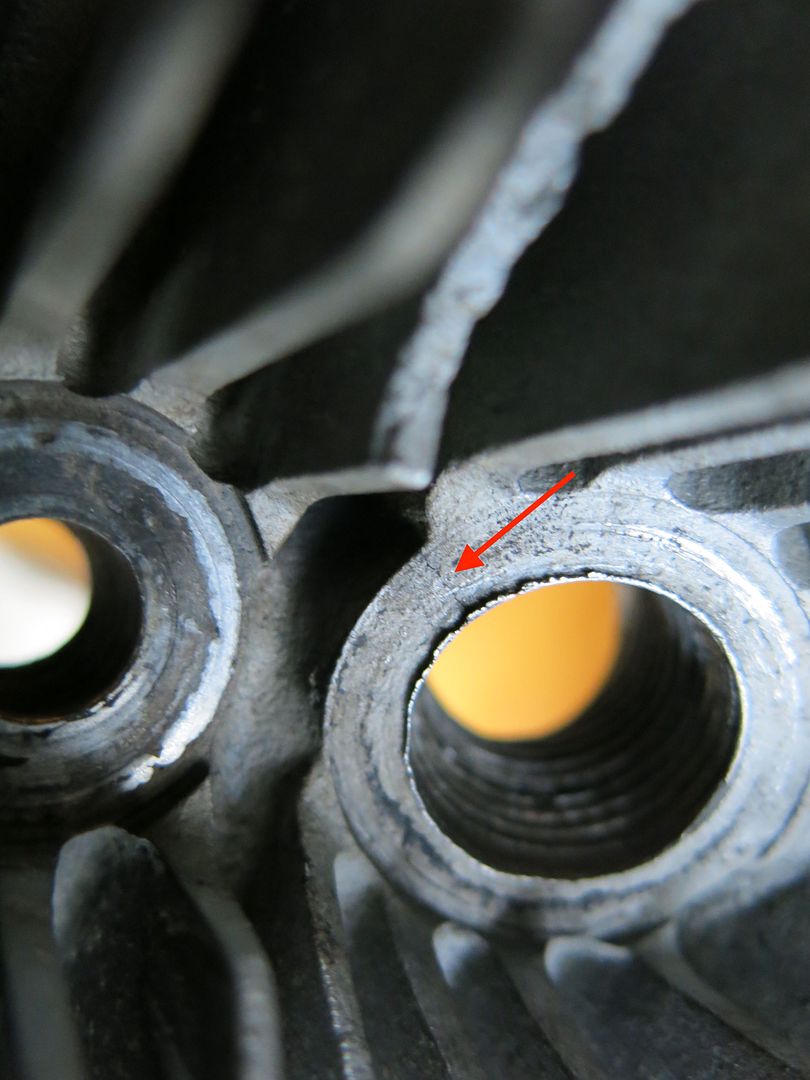

...and barely visible on the topside:

crack from the inside of the head:

...and barely visible on the topside:

Comment