I picked Ryan up at the airport last night at midnight. It was snowing in town, this picture is from outside the airport. My friend Ben Victor made the statues. They are neat.

Our main goal for the five weeks that Ryan is spending in South Dakota is to get the rolling chassis and sheet metal for the giveaway bike fit and finished. We straightened frames today, so we squeezed Ryan's Fork into the batch. The fork is n.o.s., but it was bent. The bottom legs were squeezed together.

In this pic Ryan is giving the fork the old "Johny Powers precision eyeball" The fork passed his inspection so we moved onto the front leg.

Here is the rough check for the front leg. It was bent, so we bolted our fixture between the bottom rocker holes and straightened it out.

Ryan blasted all of his hardware for his fork, and assembled the springs. The rockers were missing some of the nuts and washers. I found one washer to use as a pattern, so we made up the other three that were missing.

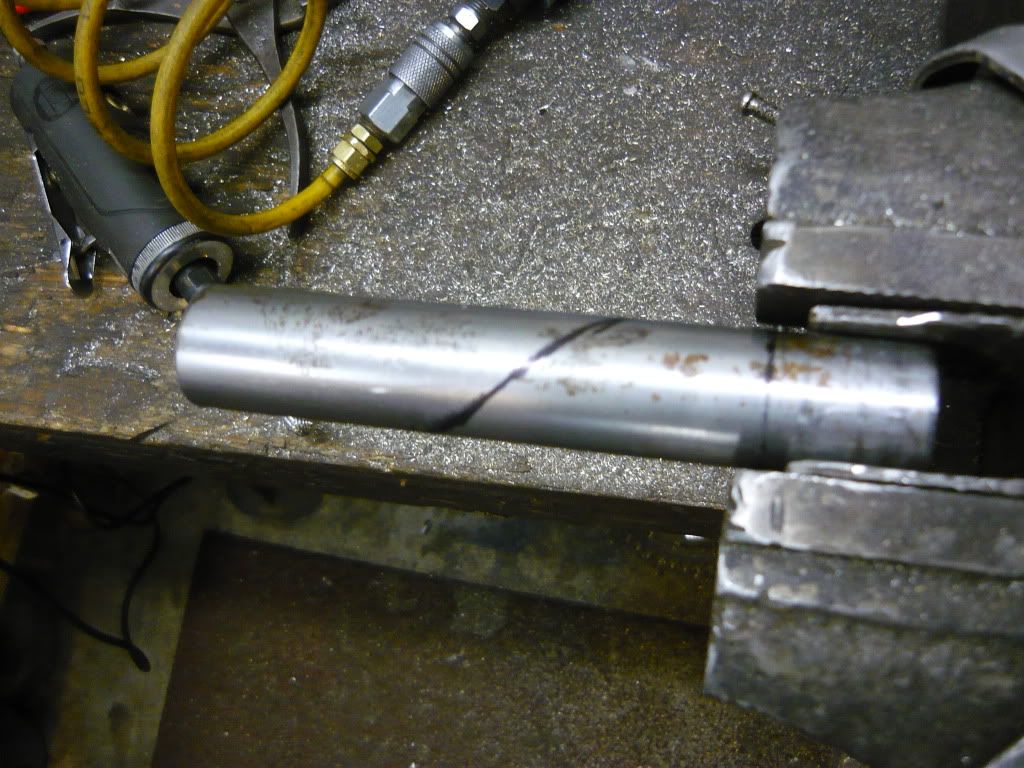

In this pic Ryan is drilling out the i.d.

After we made the three washers, I taught Ryan how to use the surface grinder to make sure that they were all the same width. The three washers were within four thousandths of being the same thickness, but it was a good opportunity to show Ryan how to use a surface grinder.

The new washers and the o.g. sample

Ryan and his new fork. We are going to work hard on getting everything assembled and fit up before we worry about painting things. This will give Ryan good practice on assembling and disassembling his bike. We will keep you posted. Have a nice night.

Comment